Custom Plush Toys Manufacturer for B2B OEM/ODM Programs

Character plush, mascot plush, stuffed animals, plush keychains—developed and produced in Guangdong, China.

Custom plush toys are soft products, but the development work is highly technical. A reliable plush factory must control pattern engineering, fabric selection, embroidery accuracy, stuffing consistency, hand finishing, packaging, and batch-to-batch repeatability.

Heyzizi is the plush toy division under Jundong. We support B2B buyers with a structured workflow—artwork review → prototype sampling → revision approval → pre-production standard → mass production → QC checkpoints → packing & shipment—so your program is easier to manage and safer to scale.

What Are Custom Plush Toys

Custom plush toys are made-to-spec soft products developed from your artwork or references. The factory converts the design into production-ready patterns, selects fabrics and fillings, applies embroidery/printing and accessories, and confirms packaging and labeling. For B2B orders, the key is repeatability—approved samples must match bulk production across batches.

Custom plush toys are often described as “soft products,” but for B2B buyers they are spec-driven manufactured goods. A custom plush is not just a shape based on artwork—it is a repeatable product standard built from patterns, materials, workmanship, branding, and packaging. The goal is simple: your approved sample must be able to turn into stable bulk production, and future reorders should match the same look and handfeel.

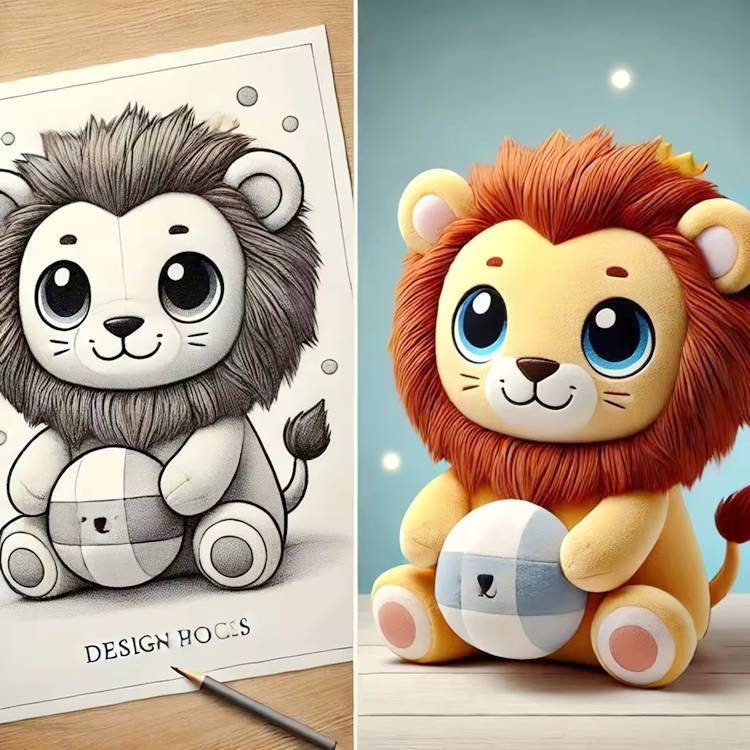

In practice, custom plush development starts with your design files or references, then moves into feasibility review, fabric and filling selection, and the right technique for details—typically embroidery, printing, or a combination. From there, the factory creates a prototype sample, collects revision notes, and locks a final approval sample as the “golden standard” for mass production.

For brands, retailers, and IP programs, the real value of a professional plush manufacturer is control: controlling face accuracy, size tolerance, stuffing consistency, attachment durability for accessories, and packaging protection to prevent deformation in shipping. This section explains how B2B custom plush projects are defined, what specifications matter most, and how to start with a clear RFQ.

Helps you decide:

- Which plush categories fit your channel (retail, promotion, IP licensing, gifting)

- What specs affect cost, MOQ, lead time, and compliance

- How sampling and QC checkpoints reduce risk before mass production

Custom Plush Toy Types We Manufacture

Most B2B buyers select plush types based on end use, sales channel, and the level of durability required for real-world handling. Below are the most common categories we manufacture. Every style can be customized with size and proportions, fabric and handfeel, filling type and firmness, branding method (embroidery/printing/labels), accessories (clothing, keychains, patches), and packaging (polybag, hangtag, barcode labeling, gift box, carton marks) to match your market and positioning.

To build a scalable plush program, we recommend starting with 2–3 core SKUs for testing—usually your main character or best-selling animal style in the most commercial sizes. Once demand is validated, you can expand into high-repeat add-ons like plush keychains, mini versions, seasonal colorways, or retail-ready gift packaging. This structure helps increase AOV (average order value), improves inventory flexibility, and supports more stable reorder frequency, while keeping development time and sampling risk under control.

Custom Plush Specifications We Confirm

Behind every custom plush lies a refined craftsmanship process. Our experienced artisans and development specialists bring together premium materials, precise pattern engineering, and controlled finishing to achieve exceptional accuracy and consistency. For brands seeking elevated plush products with flawless execution, our Guangdong facility delivers a development standard that meets global expectations.

Our Guangdong team focuses on accurate patterns, clean stitching, stable stuffing, and consistent finishing. Share your character artwork or reference image—our engineers will translate it into a production-ready plush sample with clear specs, material options, and measurable quality standards.

Size & Structure (common spec points):

- Confirm height/length (cm/in) plus key proportions like head-to-body ratio, ear/limb length, and any “must-match” silhouette rules for brand consistency.

- Define pose style (sitting / standing / lying) and clarify whether you need internal support (base plate, standing insert) to avoid collapse in display or retail use.

- Map pattern lines and seam placement so curves stay clean, shapes stay stable, and the plush body won’t twist after stuffing, handling, and shipping.

- Set tolerance rules by priority: which dimensions must be strict (overall height, head size, face zone) vs flexible (hidden seam areas) to improve bulk repeatability.

- Lock key “zone measurements” (face zone, torso width, arm/leg spacing) with reference photos, so bulk production avoids proportion drift across batches and reorders.

- Confirm functional structure details such as standing stability, bottom width, hanging points, and keychain loop placement when the plush is designed for daily carry or store display.

Fabric & Handfeel Options (keywords buyers search):

- Select fabric types by purpose: short plush / long plush / velboa / sherpa / minky / fleece, considering channel needs (retail softness, promo durability, IP look accuracy).

- Confirm pile length targets (short/medium/long) because pile changes character expression, embroidery clarity, and perceived “premium feel,” especially for close-up face areas.

- Define handfeel goals clearly—soft touch vs structured feel—and confirm whether you want a smooth surface for crisp details or a fluffy surface for a warmer look.

- Align color matching using Pantone references or physical color swatches when available, and confirm how you will approve tone (photo + daylight reference) to reduce disputes.

- Evaluate “surface behavior” for branding: which fabrics support clean embroidery edges and which may require printing to avoid fuzzy lines on high-pile plush textures.

- Confirm durability expectations—abrasion resistance, anti-pilling, and color stability—based on use case like keychains, kids handling, or high-traffic retail displays.

Filling & Weight Control:

- Confirm filling type: standard PP cotton is most common, but we also align filling grade to achieve your target handfeel, resilience, and long-term appearance.

- Choose firmness level (soft / medium / firm) and define what “firm” means for your brand—supportive shape vs squeezable comfort—so production teams can match it consistently.

- Specify stuffing distribution rules (head, body, limbs) to prevent lumps or hollow areas, especially around the face zone where uneven filling can change expression.

- Lock target weight range (grams/oz) with acceptable tolerance, because stable weight is a strong indicator of bulk consistency and helps reduce customer returns.

- If needed, add weighted inserts for sensory feel and confirm placement location, balance, and safety approach so the plush remains comfortable and stable in hand.

- Confirm shape retention standards—rebound after compression, standing stability, and “after shipping” appearance—so the plush doesn’t look flat when it reaches your warehouse.

Details & Branding Methods:

- Decide if the face/logo should be embroidered (durable, premium) or printed (fine lines, gradients, photo-style), based on detail complexity and expected handling wear.

- Confirm embroidery density and alignment for character-critical areas (eyes, mouth, cheeks) to prevent face drift, uneven expression, or thread gaps in bulk production.

- Define printing expectations (color accuracy, clarity, rub resistance) and confirm whether designs require special finishing so printed details remain clean after handling and shipping.

- List all accessories clearly—clothing, hats, ribbons, zipper pockets, keychain hardware—and confirm which are functional vs decorative to plan assembly time and stability.

- Confirm brand ID details: woven label / satin label / hangtag + barcode/SKU, plus placement and size rules so retail-ready presentation looks consistent across SKUs.

- Lock attachment methods (reinforced stitching, hidden anchors) at stress points to meet durability needs like daily keychain pull strength, retail try-on handling, or promo distribution.

Packaging & Labeling for B2B Handling:

- Choose packaging level: individual polybag for standard protection, inner box or gift box when presentation matters, and confirm pack count per carton for warehouse efficiency.

- Confirm retail-ready components: hangtags, barcode/SKU labels, and placement rules so your receiving team can scan quickly and your retail partners can display immediately.

- Align required labels—warning/care labels and any channel-specific label text—early, because labeling decisions can affect compliance and reduce rework before shipment.

- Define carton marks: PO number / SKU / quantity / destination, plus shipping labels, to minimize receiving errors and speed up distribution center processing.

- Add shape protection rules for transit: protect face embroidery, prevent crushing on structured plush, and avoid flattening on high-pile surfaces during long shipments.

- Confirm packing method to reduce deformation (carton sizing, internal arrangement, compression limits), so bulk plush arrives consistent with your approved sample appearance.

Fabric Compliance, Safety & Testing Preparation (For target markets)

- Target market & sales channel: EU/UK / US / other, retail / online / promotion

- Age grade intent: infant / toddler / kids / adult collectible (affects materials & small-part decisions)

- Small parts & attachment plan: eyes/nose accessories, keychain hardware, buttons—confirm pull strength / secure stitching and safer alternatives (embroidery/printing) when needed

- Label & documentation alignment: warning labels, care labels, barcode/SKU, carton marks—confirm what must appear for your channel

- Third-party testing support (by request): prepare sampling specs for EN71 (EU/UK) or ASTM F963 + CPSIA (US), plus any buyer-specific standards

- Pre-production risk review: confirm which areas are “character-critical” (face & silhouette) and which are “safety-critical” (small parts, seams at stress points)

Materials, Age Grading & Safety-Focused Plush Development

For B2B plush orders, the target market and age grade determine material choices, accessory decisions, and construction methods. Planning safety requirements during sampling reduces redesign risk, rework cost, and delays before mass production.

Buyers often ask “Can you do EN71 / ASTM?” The practical answer is: safety compliance starts with design decisions—fabric type, small parts, stitching strength, labeling, and production control. Tell us where you sell (US/EU/UK/other) and the intended age grade early, and we’ll recommend a safer structure and material plan.

Construction Details That Affect Safety & Durability

- Seam reinforcement at stress points (arms, legs, keychain loops)

- Embroidery thread density for long-term appearance

- Stuffing control for consistent weight and feel

- Needle control / needle detection for finished plush (when required by buyer)

Fabric & Component Selection

- Fabric surface & pile: short plush, velboa, sherpa, minky, fleece—selected by handfeel, durability, and look

- Color control: Pantone reference or physical swatches (when available)

- Accessory risk control: avoid risky small parts where required; recommend embroidery/printing alternatives

- Attachment method: stable stitching/locking methods for accessories and clothing.

Third-Party Testing Support (clear, compliant wording)

- We can produce to your target requirements and support third-party lab testing upon request. Common reference standards include EN71 (EU/UK) and ASTM F963 + CPSIA (US). Share your target market, age grade, and sales channel (retail, online, promotion), and we’ll align materials and construction accordingly.

Logo & Branding Options for Custom Plush Toys

The best branding method on plush depends on design complexity, surface texture, durability needs, and budget. We help B2B buyers choose a method that stays clear after handling, shipping, and repeat use.

Plush surfaces behave differently than flat fabrics. Some designs look premium with embroidery; others need printing for fine lines or gradients. The right choice avoids rework during sampling and improves long-term appearance.

Embroidered Logo Face

- Best for: clean shapes, premium look, long-term durability

- Buyer focus: stitch density, alignment, thread colors, border clarity

- Works well on: velboa, short plush, structured surfaces

Brand ID Options

- Woven label / satin label: place your brand name on a seam or side panel for a clean, professional finish; we confirm label size, fold type, and placement during sampling so it stays consistent in bulk.

- Hangtags + barcode labels: make the plush retail-ready with hangtags and SKU/barcode labels; we align tag style, barcode format, and attachment method (string/fastener) to support smoother inventory handling.

- Care labels / warning labels: add required care instructions and market-specific warning text where needed; we confirm the content and placement early to reduce relabeling risk before shipment.

- Custom clothing tag or patch: ideal for character outfits or fashion plush—use a woven patch, fabric tag, or badge to add premium identity on clothing; we lock the position and stitching method for repeatable results.

Placement & Consistency

Photo-based placement proof: confirm logo/face position with clear photos (front/side/back) during sampling for fast internal approval.

Measurement references: lock key distances (e.g., eye spacing, logo-to-seam distance) using measurement marks to prevent “drift” in bulk.

Production spec lock: record placement, size, and method (embroidered/printed/labels) in the production spec sheet to standardize every batch.

Consistency checkpoints: add QC checks on character-critical zones (face & silhouette) so bulk production matches the approved sample more closely.

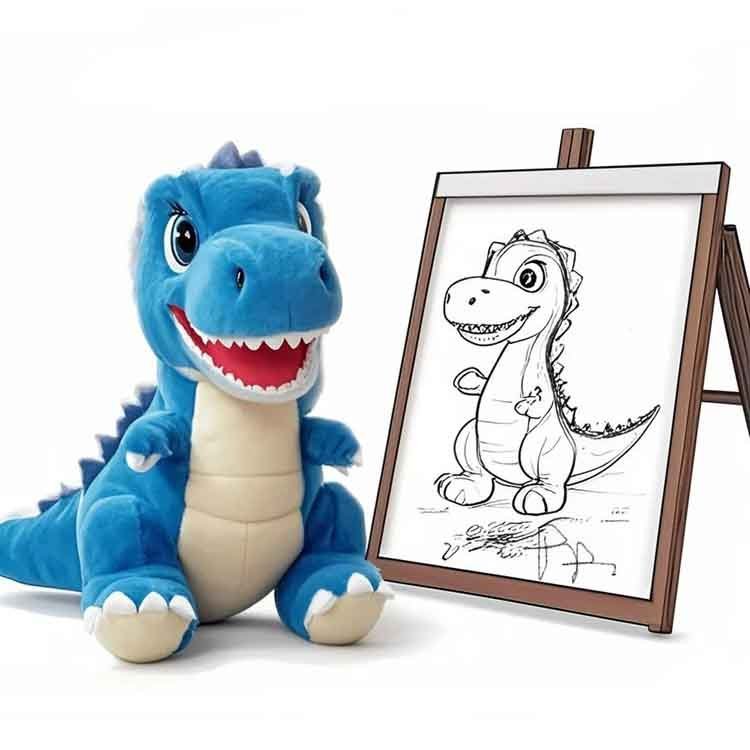

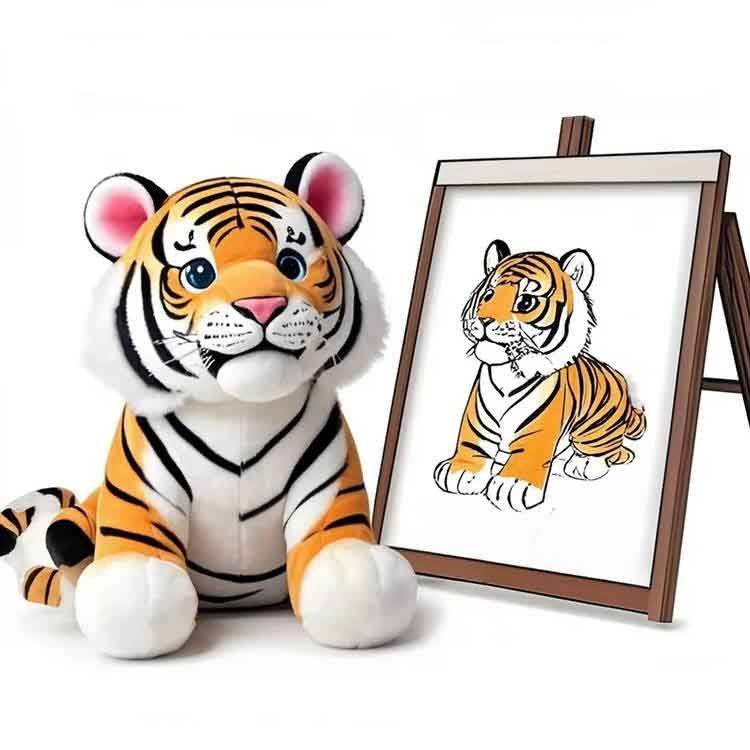

IP Character Plush Development

(2D Artwork → 3D Production-Ready Plush)

IP plush development is a translation process. The key is protecting recognizable character features while keeping the structure stable for mass production. A good factory does not only “make a sample”—it builds a repeatable spec standard.

Many character plush projects face common issues: proportions change, facial expressions drift, stitching lines look messy, or the bulk version doesn’t match the approved sample. We reduce those risks by defining clear feature priorities and building a production-ready spec.

- Pattern Engineering for Repeatability

- Define seam lines and embroidery zones for clean finishing

- Create pattern templates that keep proportions stable

- Confirm material choice to match the character style (soft vs structured)

- What we confirm before sampling (feature priority)

- Face recognition: eye shape/position, mouth expression, signature details

- Silhouette: head-to-body ratio, ear/limb size, tail shape

- Key identity elements: color blocks, accessories, clothing pieces

- Feasibility points: what should be embroidery, what should be print, what needs structure support

- How we keep bulk consistent with the approved sample

- Use the approved sample as a golden standard

- Lock measurements, embroidery placement, and accessory attachment methods

- Add QC checkpoints focused on the “character-critical” areas (face and silhouette)

Sampling, Revisions & Approval Points

Sampling is not only “making one plush.” It is the stage where specifications, appearance, durability, and packaging are confirmed. Clear approval points prevent bulk production surprises and protect your reorder consistency.

B2B buyers usually want predictable management: what you send, what we deliver, how revisions are tracked, and what becomes the final production standard. That’s why we document approvals and revision notes clearly.

Typical sampling flow

- Prototype sample — shape, face, embroidery/printing, handfeel

- Revision rounds — adjust proportion, details, stitching, color tone, accessories

- Final approval sample — locked as the golden standard for bulk

Common revision topics

- Face expression, embroidery density, eye/mouth placement

- Stitching lines and seam quality

- Fabric color tone and pile length feel

- Stuffing firmness and weight consistency

- Accessory attachment stability

- Packaging method to protect plush shape

What you receive

- Photos/videos for each sample stage

- Key measurements confirmation (size, proportion)

- Branding placement confirmation (logo/labels/hangtags)

- Revision notes (what changed and why)

- Approval checklist before bulk production

Manufacturing Details That Define Plush Quality

In custom plush manufacturing, quality is decided by repeatable details—stitching density, seam reinforcement, embroidery alignment, stuffing control, shaping, and finishing standards. These controls reduce defects and keep your bulk orders consistent with the approved sample.

Many factories describe plush as “soft and cute.” B2B buyers need something different: workmanship standards that can be repeated across thousands of units. Below are the production details we focus on because they directly affect durability, appearance, and customer experience.

Stitching & Seam Construction

- Stitch density control: stable stitch density helps prevent seam opening and keeps curves clean

- Seam reinforcement: added reinforcement at stress points (arms/legs/ears, keychain loops, hanging points)

- Seam allowance and trimming: controlled seam allowance improves silhouette and reduces bulky edges

- Hidden closure finishing: clean closing on final seams reduces visible marks and improves premium feel

Embroidery / Printing Controls

- Embroidery placement: confirmed by sample photos and measurements to avoid “drifting faces”

- Thread density & layering: prevents gaps, keeps lines crisp, improves long-term appearance

- Color selection: thread matching based on Pantone references or confirmed sample tones

- Printing durability: when printing is used, we confirm clarity, rub resistance, and color stability during sampling

Stuffing, Weight & Shape Control

- Stuffing weight targets: consistent weight improves batch consistency and reduces returns

- Firmness target: soft / medium / firm controlled by filling amount and distribution

- Shaping standards: manual shaping and correction to keep the character silhouette stable

- Weighted options: when weighted plush is requested, we control insert position for balance and comfort

Hardware Accessories & Attachment

Keychain hardware: secure stitch/locking method with reinforcement to maintain long-term pull strength during daily use

Clothing & add-ons: stable attachment and fit control to reduce detachment risk and keep the look consistent in bulk

Labels/hangtags: consistent placement and attachment method for a clean, professional brand presentation across SKUs

Quality Control, AQL Inspection & Defect Prevention

A strong QC system prevents problems early, not only at the end. For B2B plush orders, we use multi-stage checkpoints—from incoming materials to in-process inspection and final packing checks—so defects are controlled before shipment and reorders stay consistent.

Buyers usually ask “Do you do QC?” The better question is “Where do you inspect, what do you check, and how do you reduce repeat defects?” Here is how we approach QC for custom plush.

ulti-Stage QC Checkpoints (typical workflow)

- Incoming materials inspection: fabric defects, color tone, accessory integrity, filling quality

- Inline inspection: sewing quality, embroidery/printing placement, accessory attachment

- Stuffing & shaping check: weight and firmness consistency, silhouette control

- Finishing inspection: trimming, clean seams, symmetry, visual appearance

- Final inspection: appearance, labels, packaging accuracy, carton integrity

- Needle control / needle detection: for finished plush (when required)

AQL & Buyer Standards (how to align expectations)

If you have an AQL level or internal defect standards, share them early. We can align the inspection focus with your priorities—face/embroidery accuracy, size tolerance, weight consistency, accessory pull strength, and packaging requirements.

Common Defects We Actively Prevent

- Loose threads and messy trimming

- Misaligned facial embroidery (eye/mouth drift)

- Uneven stuffing (lumpy handfeel)

- Weak seams at stress points

- Incorrect label placement or missing tags

- Deformation caused by wrong packing method

Packaging, Labeling & Shipping-Ready Preparation

For plush toys, packaging affects product shape, retail readiness, and receiving efficiency. B2B buyers often need hangtags, labels, barcodes, and carton marks that match their warehouse and sales channel requirements.

A plush that looks perfect on the sample table can arrive deformed if packing is wrong. That’s why we confirm packaging specs before shipment, especially for character plush with structured faces or large sizes.

Common Packaging Options

- Individual polybag (standard protection)

- Hangtag + barcode label (retail-ready and inventory-friendly)

- Inner box / gift box (when presentation is important)

- Master carton with carton marks (shipping and receiving clarity)

Labeling & Compliance-Related Items

- Care labels / warning labels (based on target market)

- Barcode labels (SKU management)

- Carton marks (PO number, SKU, quantity, destination)

Anti-Deformation Packing Tips

- Adjust packing method for giant plush and structured character plush

- Protect high-embroidery areas to prevent flattening

- Confirm carton size and internal arrangement to reduce crushing risk

MOQ, Pricing Drivers & How to Reduce Unit Cost

We support trial orders for testing, but plush production still requires full development and setup—pattern, sampling, material sourcing, line preparation, QC, and packing. That’s why small orders usually have higher unit costs than bulk orders.

B2B buyers often want two answers: “What is the MOQ?” and “How do we optimize cost without losing quality?” Below is how pricing typically works in plush manufacturing.

Small Order vs Bulk Order (clear comparison)

| Item | Small Order | Bulk Order |

|---|---|---|

| Unit Cost | Higher | More competitive |

| Material Pricing | Less leverage | Better material rates |

| Production Efficiency | Lower | Higher line efficiency |

| Best Use | Market testing | Long-term programs & reorders |

Main Pricing Drivers (what affects cost the most)

- Size and pattern complexity (more pieces, complex shapes)

- Embroidery/printing density (thread time and machine time)

- Accessories and clothing (additional materials and labor)

- Fabric type and sourcing (special plush fabrics may increase cost)

- Safety/compliance requirements (material choices, labeling needs)

- Packaging requirements (gift boxes, special protection)

Cost Optimization Suggestions (buyer-friendly, not pushy)

- Start with 2–3 core SKUs and reduce unnecessary accessories for the first run

- Choose embroidery only where it matters most (face/logo), and simplify hidden areas

- Standardize packaging for trial orders, upgrade for retail when volume stabilizes

- Plan compliance requirements early to avoid redesign after sampling

Lead Time, Production Planning & Shipping Support

Lead time for custom plush toys depends on sample complexity, revision rounds, material readiness, order quantity, and packaging requirements. A professional plush manufacturer provides a sampling plan first, then confirms a realistic production schedule after the approval sample is locked.

B2B buyers often plan launches, retail drops, or promotions. What matters most is predictability. We help you estimate timing from artwork review → sample approval → mass production → final QC → packing → shipment, based on your program requirements.

- Typical Timing

- Artwork review & feasibility: 1–2 business days

- Prototype sampling: commonly 3–7 days (varies by structure and details)

- Revisions: depends on change scope and number of rounds

- Mass production: depends on quantity, complexity, and line schedule

- Final QC & packing: depends on packing type and labeling needs

We will confirm a project timeline after reviewing your specs and sampling plan.

- What Impacts Lead Time the Most

- Complex embroidery/printing or multiple techniques

- Special fabrics or accessories that need sourcing

- High-detail character faces (more development time)

- Weighted inserts / sound / LED / motion features

- Packaging and labeling requirements (hangtags, barcode, gift box)

- Compliance requirements and testing timeline (if applicable)

- Shipping Options

Sea freight: Lowest cost for bulk, heavy shipments.

Air freight: Fast delivery for mid-volume urgent orders.

Express courier: Door-to-door speed for samples and small parcels.

- Packing optimization to reduce deformation and transit damage

- Carton marks and barcode labeling for smoother receiving

RFQ Checklist for Custom Plush Toys

A complete RFQ helps you get a faster and more accurate quote. If you send the items below, we can reply with material suggestions, a sampling plan, and a practical cost estimate.

A clear RFQ is the fastest way to get an accurate quote and a realistic sampling plan for custom plush toys. Many delays happen when key details are missing—size, quantity, target market, artwork, branding method, accessories, or packaging. With a complete checklist, we can quickly confirm materials and handfeel options, recommend embroidery vs printing, flag small-part or durability risks, and estimate MOQ, lead time, and unit cost with fewer back-and-forth messages.

Use the RFQ checklist below to share your requirements in one go. It helps your team compare suppliers fairly, keeps sampling revisions under control, and sets a stable standard for bulk production and reorders.

RFQ Checklist (what to include)

- Plush type (character / mascot / animal / keychain / weighted / giant)

- Size (cm/in) + target weight (if relevant)

- Quantity (trial order + expected reorder volume)

- Target market + age grade (US/EU/UK/other)

- Artwork files (AI/PDF preferred) or reference images

- Branding method (embroidery / print / woven label / hangtag)

- Accessories (clothing, keychain hardware, special features)

- Packaging needs (polybag / hangtag / box / barcode / carton marks)

- Target deadline (launch date or delivery window)

Copy-Paste RFQ Email Template

Hello Heyzizi Team,

We are looking for a B2B custom plush toy manufacturer for the following project:

- Plush type:

- Character / reference images (attached):

- Size (cm/in):

- Quantity (trial + future reorder expectation):

- Target market & age grade:

- Branding method (embroidery/print/labels):

- Accessories / special features:

- Packaging requirements (hangtag, barcode, box, carton marks):

- Target deadline:

Please advise material suggestions, sampling timeline, MOQ, and a quotation. Thank you.

Request a Custom Sample First?

If you have artwork, logo files, or even just an idea, please share your project details—size, target fabric, color reference, and customization requirements. We’ll recommend suitable materials and provide a clear sampling plan to bring your custom plush toy design to life.

What Makes Our Custom Plush Production Reliable for B2B

Trust is built through predictable execution—clear approvals, documented specs, quality checkpoints, and packing confirmation. We focus on making your plush project easier to manage and safer to scale.

For B2B buyers, “reliable” plush production is not about making one nice sample—it’s about delivering repeatable bulk quality, stable lead times, and clear project control from artwork review to shipment. What makes our custom plush program dependable is the way we manage the details that most often cause problems in mass production: face accuracy, proportion stability, embroidery/printing consistency, stuffing weight and firmness control, and secure attachment for keychains, clothing, and accessories.

We build reliability through a structured workflow: we confirm a practical spec checklist before sampling, document revision notes, and lock the final approval sample as a golden standard for production. During manufacturing, we apply multi-stage QC checkpoints (not just a final check) to prevent drift early, especially in character-critical zones like the face and silhouette. Before shipment, we also verify packaging and labeling—including hangtags, barcode/SKU labels, care/warning labels, and carton marks—so your receiving and retail handling are smoother and your products arrive with less risk of deformation.

This section explains the controls, proof points, and deliverables B2B teams rely on to scale plush projects with confidence—and to reorder without surprises.

Process Proof

- Clear sampling-to-production approvals (prototype → revisions → final approval sample)

- Spec confirmation before bulk production (size, materials, logo placement, packaging)

- Revision notes that keep decisions traceable

- Golden standard concept for repeat orders

Quality Proof

- Multi-stage QC checkpoints across sewing, embroidery/printing, stuffing, finishing

- Needle control / needle detection option for finished plush (when required)

- Inspection focus on character-critical areas (face and silhouette) for IP plush

Delivery Proof

Packaging and labeling confirmation before shipment (photo proof + checklist)

Barcode and carton mark support (when required) (SKU/PO/qty/destination)

Packing suggestions to reduce deformation during transit (anti-crush, face protection)

Frequently Asked Questions

Can you develop a plush from a simple sketch or reference image?

Yes—we can start a B2B custom plush project from a simple sketch, a reference photo, or a character sheet. What matters is not how “perfect” the first input is, but whether we can confirm the key specs that control how the final plush looks and feels in mass production. In plush development, the biggest risk is not making a sample—it’s making a sample that cannot be repeated consistently in bulk.

To move from a sketch to a production-ready plush, we focus on four areas early:

- Shape & proportion: We confirm overall size (cm/in), head-to-body ratio, and silhouette (standing/sitting/lying). Even a rough sketch works if you can point out what must stay consistent (for example, “round head,” “short arms,” “tall ears”).

- Face & identity features: For character plush, the “face zone” is critical. We confirm eye placement, mouth expression, and signature details. If facial details are complex, we’ll advise whether embroidery or printing is more stable.

- Fabric & handfeel: Plush fabrics can change the look dramatically. We’ll recommend fabric types based on the style you want: smoother surfaces for crisp details or higher pile for a softer feel.

- Accessories & safety considerations: Keychains, clothing, patches, or small parts should be planned early, especially if you sell in markets with age grading and safety expectations.

To speed things up, you can send any of the following: (a) one front-view image + notes, (b) front/side/back references, (c) an existing similar sample you like, or (d) brand guidelines for color and finishing.

What you’ll get from us is a structured start: feasibility feedback, a sampling plan, and a clear list of questions needed to lock the first prototype. This approach is designed for B2B buyers who need predictable sampling and stable reorders.

What information do you need to quote a custom plush project accurately?

An accurate quote for custom plush toys depends on whether we can define the full scope of materials, workmanship, and packaging—because plush pricing is driven by labor time and construction complexity, not just “size.” For B2B purchasing, a fast quote is helpful, but a complete quote is what prevents surprise costs during sampling or mass production.

Here is the information that gives the highest quoting accuracy, with the practical reason for each item:

| Info Needed | Why It Matters for Pricing / Lead Time |

|---|---|

| Plush type (character/animal/keychain/weighted/giant) | Defines structure complexity and use-case durability requirements |

| Size (cm/in) + target weight (if needed) | Controls material consumption, pattern pieces, stuffing volume |

| Quantity (trial + reorder expectation) | Impacts material pricing leverage and production efficiency |

| Target market + age grade | Influences material selection, small-part choices, labeling needs |

| Artwork / reference images | Determines embroidery vs printing, face complexity, revision risk |

| Branding method (embroidery/print/labels/hangtags) | Impacts machine time, placement control, and finishing steps |

| Accessories (clothing, hardware, sound/LED, etc.) | Adds parts, labor steps, sourcing time, assembly complexity |

| Packaging needs (polybag/hangtag/box/barcode/carton marks) | Affects packing cost, labeling setup, shipping protection requirements |

| Target deadline / delivery window | Helps align sampling schedule and production planning |

If you don’t have everything ready, you can still request a preliminary range quote—but for procurement teams, we recommend sending at least: plush type + size + quantity + target market + artwork. That allows us to propose workable fabric options and estimate the production effort.

A professional plush quote should also clarify assumptions: whether the face is embroidered or printed, whether accessories are included, and what packaging level is expected. This transparency is important for B2B decision-making because it makes supplier comparisons fair and helps you avoid quoting “apples vs oranges.”

If you want the quickest accurate path, use a one-page RFQ checklist (we can share the format) and include your priorities: target price range, quality level, and channel (retail, promotion, IP merchandise). That allows us to recommend the right construction and keep your project on schedule.

What affects sample cost and sampling time the most?

Sample cost and sampling time for a custom plush toy are mainly driven by how much engineering and manual work is required to turn your design into a stable, repeatable product. For B2B buyers, sampling is not a formality—it’s the stage where the final production standard is built. When buyers understand the cost/time drivers, they can plan budgets and avoid unnecessary revision loops.

The biggest drivers are:

- Pattern complexity (number of pieces): A simple plush may use fewer pattern panels; complex shapes, layered structures, or detailed silhouettes require more pieces and more sewing steps. More pieces usually means more risk of shape deviation in bulk, so the sample phase may require extra control.

- Face detail level: Character plush often needs careful work in the face zone. Embroidery density, thread layering, and placement accuracy are time-consuming. If the facial design includes gradients or ultra-fine lines, sampling may require testing printing methods to keep details crisp.

- Accessories and clothing: Clothing, hats, keychains, pockets, patches, or hard components add both sourcing and assembly time. They also increase revision topics (fit, position, stability).

- Special features: Weighted inserts, sound modules, LED, motion features, or structured standing support require additional development steps and safety considerations.

- Material sourcing: If a special plush fabric color or texture is required, sourcing can affect timeline—especially if the project needs exact handfeel or a unique pile length.

- Compliance planning and packaging: If the project must align with a target market and age grade, we may need to recommend alternative details (for example, avoiding small parts) and confirm labeling and packaging requirements during sampling.

To manage sampling efficiently, we recommend a clear revision approach: identify what must be perfect first (face, proportion, branding placement), then refine secondary details. This reduces endless cycles. Many B2B projects confirm within 1–3 revision rounds when feedback is structured.

From a purchasing viewpoint, the sample is “expensive” only when it is treated as a one-time task. When the sample becomes the golden standard—with locked measurements, workmanship, and packaging instructions—it lowers defect risk and improves consistency for reorders, which saves cost long-term.

How many sample revisions are typical?

For B2B custom plush projects, 1–3 revision rounds is common, but the actual number depends on how clear the initial requirements are and how complex the character features are—especially the face. Revisions are normal in plush development because a 2D design often changes when translated into a 3D soft product. The key is not avoiding revisions; it’s keeping revisions structured and traceable so the project converges quickly.

A typical revision process looks like this:

- Prototype sample: Confirms overall shape, proportion, basic face placement, fabric handfeel, and initial branding approach.

- Revision rounds: Refine the face (expression, embroidery density, eye spacing), adjust silhouette (ear/limb proportions), improve seam lines and finishing, confirm accessory stability, and finalize packaging approach.

- Final approval sample: Locks the standard for bulk production and becomes the reference for QC and repeat orders.

What causes revision counts to increase? The most common factors are (1) unclear “must-have” priorities, (2) changing artwork mid-sampling, (3) uncertain fabric choices (pile length changes the look), and (4) adding accessories late in the process. When buyers provide precise direction early—what must match the IP identity and what can be flexible—revision rounds usually stay within a manageable range.

For procurement teams, the most effective way to shorten revisions is to standardize feedback. We recommend sending feedback in a short list format:

- Must change: (critical items)

- Optional improvements: (secondary items)

- Confirmed OK: (items to lock and not revisit)

This approach protects timeline and prevents “moving targets.” It also makes approvals easier internally when multiple stakeholders (brand, licensing, retail) are involved.

Finally, a revision should always be connected to a production reality: if a change makes the plush fragile, unstable, or inconsistent in bulk, the factory should advise alternatives that achieve the visual goal without risking repeatability. That’s how revisions become a professional development step rather than trial-and-error.

Do you support low MOQ or trial orders?

Yes, we support trial orders / small batch production for B2B buyers who need market testing, pilot runs, or pre-launch validation. That said, it’s important to understand how MOQ and pricing work in plush manufacturing so expectations are aligned from the beginning.

Even when the order quantity is small, the factory still needs to complete the full workflow: pattern engineering, sampling, material planning, production setup, quality checkpoints, and packing preparation. Plush is not a simple “print-and-ship” product. Because the setup and development effort is similar whether you produce 100 units or 5,000 units, the unit cost for small orders is usually higher.

Here’s a clear B2B comparison:

| Topic | Trial / Small Order | Bulk Order |

|---|---|---|

| Unit Cost | Higher (setup cost spread over fewer units) | More competitive |

| Material Cost | Less leverage | Better rates |

| Line Efficiency | Lower | Higher |

| Best For | Testing and validation | Reorders and scaling |

To make trial orders efficient, we often recommend a strategy that protects both cost and quality:

- Start with 2–3 core SKUs instead of too many variations.

- Use standard packaging for the trial run, then upgrade to full retail packaging once demand is proven.

- Keep accessories minimal in the first run unless they are essential for brand identity.

- Lock the “golden standard” sample carefully, because repeat orders are where the real cost advantage appears.

For B2B buyers, the real value of a trial order is not just selling the first batch—it’s proving the program can be repeated. If the sample standard is confirmed well, bulk production becomes smoother, defects reduce, and pricing improves due to material leverage and production familiarity.

If you want to proceed, share your quantity plan (trial + expected reorder), and we can advise a practical MOQ path. For example, some product types (like plush keychains) can be more MOQ-friendly due to smaller size and standardized structure, while complex character plush with clothing may need a more stable volume plan.

How do you keep mass production consistent with the approved sample?

Keeping mass production consistent with the approved sample is one of the most important requirements for B2B plush programs—especially for brands and IP projects where small changes in face or proportion can damage product identity. We approach consistency as a system: golden standard + locked specs + checkpoints + packaging confirmation.

First, we treat your final approval sample as the golden standard. This is not just a “nice sample”; it becomes the reference that production and QC use to verify bulk output. During the approval stage, we confirm what must be strictly controlled, such as:

- Measurements (height, key proportions, head-to-body ratio)

- Face accuracy (eye placement, embroidery density, expression)

- Branding placement (logo position, labels/hangtags)

- Stuffing targets (weight range, firmness level)

- Accessory attachment methods (keychain hardware, clothing stability)

- Packaging method (to protect shape)

Second, we convert approvals into a production-ready spec approach. A plush program becomes consistent only when details are written into a repeatable standard rather than held in memory. For example, it’s not enough to say “make the eyes a bit higher.” We confirm with photos, measurements, and positioning references.

Third, we use multi-stage QC to catch drift early. Consistency problems usually grow when they are discovered only at the end. That’s why checks during sewing/embroidery and during stuffing/shaping matter. If your project has “character-critical areas” (face and silhouette), we prioritize them for inspection focus.

Finally, we confirm packaging before shipment. Many bulk consistency complaints are actually packaging issues—plush arrives deformed, embroidery looks flattened, or accessories are bent. A packaging confirmation step helps protect the approved appearance during transit.

For B2B buyers who manage reorders, this system is what creates stability over time: each reorder references the same golden standard and the same locked specs, which helps keep your product line consistent even as volumes grow.

Can you do embroidered faces and fine facial expressions?

Yes. Embroidered faces and stable facial expressions are a core requirement for many custom character plush programs. In B2B plush manufacturing, facial quality is not only about looking good in photos—buyers need the face to remain consistent across bulk production and across reorders. That requires control of placement, thread density, layering, and fabric behavior.

We manage embroidered face development in a structured way:

- Face zone mapping: We define the embroidery zone and seam lines so embroidery does not distort when the plush is stuffed and shaped. Without this planning, eyes can “drift,” and expressions can change between units.

- Thread density and detail balance: Higher density can create cleaner lines, but over-dense embroidery may stiffen the fabric or cause puckering. We balance density so the face looks sharp while staying smooth and natural on plush surfaces.

- Alignment and symmetry control: Facial embroidery must be positioned consistently. During sampling, we confirm alignment with photos and measurement references (for example, distance between eyes, distance to seam lines).

- Fabric selection for face clarity: Not all plush fabrics show embroidery equally. If the pile is long or fluffy, embroidery edges can look softer. For designs requiring crisp edges, we may recommend smoother plush surfaces in the face area or adjust technique.

- When printing is better: Some faces include gradients, ultra-fine lines, or photo-style details that embroidery cannot reproduce cleanly without heavy cost. In those cases, printing may provide better fidelity and more consistent results.

From a buyer perspective, the best way to ensure face quality is to lock priorities early: What must be exact (expression and eye position) and what can be slightly flexible (minor stitch texture). We then incorporate those priorities into the approved sample standard and QC focus areas.

If you have a licensed character or strict brand guidelines, share the key visual rules. We can then plan a face development approach that protects identity and supports repeatability in mass production.

Can you add clothing, keychains, or special accessories?

Yes. Clothing and accessories are common in B2B plush programs, especially for IP character plush, promotional mascots, and retail collections. However, accessories are also a common source of quality complaints if they are added late or attached without a stable method. Our approach is to treat accessories as part of the product engineering, not as an afterthought.

We typically support accessories such as:

- Clothing (shirts, hoodies, dresses, uniforms)

- Hats, scarves, ribbons, or patches

- Keychain hardware (plush keychains, bag charms)

- Functional details (zipper pocket, mini pouch, tags)

- Optional features like weighted inserts, or feature modules when the project requires it

For B2B buyers, there are three practical considerations:

- Attachment durability: A keychain plush requires stronger attachment than a display plush. We recommend secure stitching methods and reinforcement at stress points, especially around loops and hardware. Clothing also needs stable methods to avoid loose parts during handling.

- Consistency in bulk: Accessories introduce more variables: fabric thickness, sizing, alignment, and assembly. During sampling, we confirm the attachment method and placement, then lock them in the production spec.

- Packaging protection: Accessories can deform during shipping (bent hardware, crushed hats). Packaging must protect shape and reduce transit damage, especially for retail-ready products.

We recommend deciding accessories early during sampling because they influence both cost and lead time. Adding accessories after the face and body are already approved can trigger additional revisions and can impact MOQ or sourcing schedule.

If your project is for retail, we can also align accessories with private label needs—such as woven labels, hangtags, barcode labels, and carton marks—so the product is easier to sell and manage in inventory.

Do you support EN71 / ASTM F963 / CPSIA compliance projects?

We can support compliance-focused B2B plush projects by producing to your target market requirements and supporting third-party lab testing upon request. The most important point for buyers is this: compliance is not a single checkbox at the end—it is influenced by choices made during design, materials, accessories, labeling, and process control.

Here is a practical way to think about compliance planning:

| Buyer Input | What We Align During Development |

|---|---|

| Target market (EU/UK, US, etc.) | Recommended material and labeling direction |

| Age grade (infant/toddler/child/adult collectible) | Small-part approach, accessory decisions, safety-focused construction |

| Sales channel (retail / online / promotion) | Packaging/label expectations and documentation needs |

| Product features (keychain, weighted, sound/LED) | Attachment methods and risk control planning |

Common reference standards include EN71 (EU/UK) and ASTM F963 + CPSIA (US). Buyers may also have additional internal requirements. If you share your channel and age grade early, we can recommend:

- Whether to avoid or redesign small parts

- Which branding method is safer (embroidery/printing) for the design

- How to handle labels and warnings in packaging

- Workmanship choices that support durability and reduce defect risk

We do not position compliance as a marketing claim. Instead, we treat it as a development requirement: confirm the right structure during sampling and keep process control stable during mass production. If testing is required, the best time to plan is during sampling, because late changes after bulk production begins are expensive and can cause delays.

If your team already works with a specific lab or has a known test plan, share it. That helps align the product structure and materials to reduce risk of redesign.

What packaging options do you offer for B2B orders?

For B2B plush orders, packaging is not only about presentation—it affects shape protection, retail readiness, inventory handling, and shipping damage risk. Plush is sensitive to compression; wrong packing can flatten embroidery, deform structured faces, or cause creases that buyers interpret as quality issues.

We commonly support packaging options such as:

| Packaging Item | Typical B2B Purpose |

|---|---|

| Individual polybag | Standard protection, keeps plush clean |

| Hangtag | Branding and retail display |

| Woven label / satin label | Professional brand identification on the product |

| Barcode label | SKU management and warehouse scanning |

| Care label / warning label | Market/channel requirements and consumer info |

| Inner box / gift box | Premium presentation and better shape protection |

| Master carton + carton marks | Shipping clarity and receiving efficiency |

For B2B programs, the best packaging choice depends on your channel:

- Retail programs often need hangtags, barcode labels, and clear carton marks for receiving.

- Promotional giveaways may prioritize cost-effective packaging but still require clean labeling and safe shipping.

- IP/character products often need stronger shape protection to maintain facial expression and silhouette.

We also recommend confirming packaging early during sampling, especially for giant plush, weighted plush, or character plush with structured features. Packaging decisions can affect labeling layout and can influence testing requirements in compliance-focused markets.

Finally, we provide packing suggestions to reduce deformation in transit: carton sizing, internal arrangement, and protection for high-embroidery areas. This is a practical step that protects your product’s first impression when it arrives at your warehouse or retail partner.

What lead time should we plan for?

Lead time planning for custom plush toys should be approached as a schedule built around approval points. For B2B buyers, the most reliable timeline is not a single number—it’s a staged plan that includes sampling, revisions, production, QC, packing, and shipment. The reason is simple: plush development often requires changes, and those changes can affect both cost and timing.

A practical schedule usually follows these stages:

- Artwork review & feasibility: We confirm what is achievable, identify risk points (face complexity, accessories, special fabrics), and propose a sampling plan.

- Prototype sample: This is the first physical translation of your design. Time depends on structure complexity and materials.

- Revisions: The revision phase is the biggest timing variable because it depends on how many changes are needed and how quickly approvals are confirmed.

- Final approval sample (“golden standard”): Once approved, we can lock the production standard and confirm the production schedule more accurately.

- Mass production + QC checkpoints: Production time depends on quantity, complexity, line planning, and quality requirements.

- Final inspection + packing: Packing type and labeling requirements (hangtags, barcodes, boxes, carton marks) affect finishing time.

- Shipment: Sea/air/express selection affects overall delivery window.

What affects lead time the most? High embroidery density, special fabrics, complex character faces, added accessories, and compliance/testing timelines. For B2B teams, the best way to protect your timeline is to send a complete RFQ, approve samples with clear priorities, and avoid adding major features late.

We recommend planning your program backward from your target launch date: allow time for sampling + revisions + production + shipping buffer. If you share your deadline early, we can propose a realistic plan and identify which design choices may speed up or slow down the schedule.

How do we start a project quickly?

Starting quickly in a B2B custom plush project means reducing uncertainty in the first 48–72 hours. The fastest projects are not the ones that skip steps—they are the ones where requirements are clear, feedback is structured, and approvals are aligned early.

To start efficiently, we recommend a three-step approach:

Step 1: Send a complete RFQ package

At minimum, provide plush type, size, quantity, target market + age grade, and artwork/references. Add branding and packaging preferences if known. This allows us to propose material options and a sampling plan without endless back-and-forth.

Step 2: Confirm priorities before the first sample

Decide what is non-negotiable: for example, the exact facial expression, the silhouette, the brand logo position, and the handfeel level. Plush sampling can become slow when stakeholders keep changing “the most important part.” If you align priorities internally, the factory can execute faster.

Step 3: Approve with a structured revision list

When you review the prototype sample, provide feedback in a short list: must change, optional, confirmed OK. This keeps revisions controlled and speeds up final approval.

For brands and IP programs, we also recommend planning for repeatability: treat the final approval sample as a golden standard and lock the key specs (measurements, embroidery placement, stuffing target, accessory attachment, and packaging method). That makes mass production smoother and reduces reorder risk.

If you prefer email communication, you can send your RFQ to info@heyzizi.com with your artwork attached. We will reply with a practical plan: feasibility notes, material suggestions, sampling timeline, and quotation assumptions, so your procurement team can make decisions quickly.

Start Your Custom Plush Project Today

If You Can imagine it,We Will Create it!

Whether you are a brand, creator, retailer, or agency, our Guangdong plush factory is ready to support your OEM/ODM development. Send us your design, concept, or reference image — our team will reply with a free development proposal and quotation.

1. Tell Us What You Need

Tell us your requirements and share your artwork or reference images.

2.Get a Solution & Quote

We’ll suggest the best solution based on your requirements, and provide a detailed quote within 12 hours.

3.Approve for Mass Production

We will start mass production after getting your approval.

For all inquiries, please feel free to reach out at

- info@heyzizi.com

- (+86)13717153084

Ready to Grow Your Plush Product Line?

Brands and businesses from over 80 countries have chosen Jundong as their trusted plush manufacturing partner. Now it’s your turn. Work with us for reliable custom plush production, clear sampling support, and stable delivery for long-term programs.