MOQ & Pricing for Custom Plush: What Drives Cost, Trial vs Bulk Logic, and Sampling Cost Factors

Most new plush projects don’t fail because the idea is weak. They fail because pricing feels unpredictable. One factory says MOQ is 300, another says 1,000. One quote looks cheap until “sample fees,” “packing fees,” or “embroidery costs” show up later. stuck: either rush decisions to hit a launch date, or slow down and lose momentum.

Here’s the uncomfortable truth: plush pricing is not “mysterious,” but it is easy to misunderstand. Plush is a labor-heavy product. It depends on pattern work, sewing efficiency, embroidery/printing choices, and material purchasing realities (fabric yardage, trims, hardware). That’s why the same-looking plush can cost very different amounts when you change size, seam complexity, accessories, or quantity. It’s also why “low MOQ” can be real, but the unit price often climbs—because the factory still runs almost the same process, just spread across fewer units.

MOQ and pricing in custom plush are driven by fixed setup work and variable production costs. MOQ exists because factories must cover material sourcing, cutting and sewing setup, QC, and packing preparation. Trial orders usually cost more per unit because those fixed costs are spread across fewer pieces, while bulk orders gain lower unit pricing through better efficiency and purchasing. Sampling fees vary mainly by pattern complexity, embroidery stitch count, special fabrics, and accessory development.

What does MOQ mean for a custom plush manufacturer, and why do factories set minimums?

In custom plush, MOQ is the minimum quantity a factory will produce for a specific style/character, often affected by fabric yardage, accessory minimums, and line setup time. Factories set MOQs to cover real fixed work: sourcing, pattern making support, cutting layout, line balancing, QC paperwork, and packing prep. Lower MOQ is possible, but unit pricing usually rises because those fixed costs don’t shrink much when quantity shrinks.

MOQ is one of the most misunderstood terms in plush sourcing, so let’s ground it in how factories actually run. When a factory quotes “MOQ 300,” it rarely means “we love the number 300.” It usually means: below that quantity, the project still consumes almost the same setup workload, but the factory can’t spread that workload across enough units to keep unit pricing and scheduling reasonable.

What is the MOQ for custom plush toys? (per style, size, color, character)

In plush, MOQ often applies per design. That can mean:

- Per character (one plush design = one MOQ)

- Per size (same character in 10” and 15” may be treated as two styles)

- Per colorway (a dyed fabric color or unique print can change the MOQ logic)

This is why sometimes feel tricked: they think they’re ordering “500 pieces total,” but the factory sees “250 of Style A + 250 of Style B,” each needing setup, fabric planning, and QC tracking.

MOQ vs “minimum fabric yardage” vs “minimum accessory order”

A plush MOQ is often limited by upstream suppliers, not only the plush factory:

- Fabric minimums: some fabrics, colors, or custom dye lots require minimum yardage

- Accessory minimums: eyes, noses, keychains, zippers, woven labels can have supplier minimums

- Packaging minimums: custom printed boxes, hangtags, or polybags may have minimum runs

So you can have a factory that can sew 200 units, but the fabric or accessories can’t be purchased economically at that level.

Why factories set MOQs (the real list)

MOQs exist because plush production includes fixed tasks:

- cutting layout planning (pile direction, nesting efficiency)

- sewing line setup and training (especially for new designs)

- QC standards, checklists, and defect examples

- packing SOP (folding/shape protection, labeling, carton marks)

- purchase orders, tracking, and coordination time

Those tasks still happen whether you make 200 or 2,000.

Low MOQ vs standard MOQ — what changes in unit price and risk

Low MOQ can be a smart start for new customers. But here’s the trade:

- Unit price goes up (fixed work spread over fewer units)

- Material choices may be limited (you may need stock colors instead of custom-dyed fabric)

- Production scheduling can be tighter (factories prioritize larger runs in peak seasons)

Friendly way to plan is to treat MOQ as a strategy, not a fight. If your goal is to test demand, you can start lower—then build a clean path to bulk where your unit cost drops when you reorder. That “step plan” is usually more realistic than forcing an unrealistically low MOQ that creates quality shortcuts.

What MOQ really controls

| MOQ driver | What it affects | What you can do |

|---|---|---|

| Fabric yardage minimum | color options, cost | choose stock colors, consolidate SKUs |

| Accessory minimum | hardware/eyes/labels | standardize trims across styles |

| Line setup time | unit price at low qty | plan trial → bulk breakpoint |

| Packing requirements | labor + materials | simplify retail packaging for trial |

If you share your plush type, size, and how many SKUs you want, Heyzizi can recommend a best MOQ strategy for balances cost and launch speed.

Which cost drivers impact custom plush pricing the most: size, materials, design complexity, and accessories?

The biggest plush pricing drivers are size/weight, fabric type, pattern complexity, embroidery stitch count vs printing, and accessories (clothes, props, keychains, zippers). “Small” is not always cheaper if the design has tight curves, many parts, or heavy embroidery. Accessories raise costs because they add sourcing steps and extra operations. The fastest way to control price is to simplify structure and standardize materials across SKUs. (Funenjoy: Plush Toy Manufacturing)

If you’ve ever asked for a plush quote and thought “this seems high for a soft toy,” you’re not alone. Plush cost is not just fabric + stuffing. It’s time. It’s how many pieces must be cut, how many seams must be sewn, how carefully the face must be aligned, and how many extra operations happen after sewing (trims, clothing, keychains, packaging).

What factors drive plush toy pricing?

Most quotes can be understood by separating cost into five buckets:

- Materials (fabric, backing, stuffing, thread, trims)

- Labor (cutting + sewing + stuffing + finishing)

- Decoration (embroidery stitch count or printing) (Funenjoy: Plush Toy Manufacturing)

- Accessories (hardware, clothing, zippers, labels)

- QC + Packing (inspection time, polybag/hangtag/carton)

If a factory can’t explain pricing using buckets like these, it’s hard to compare suppliers fairly.

Size and pattern complexity — why “small” is not always cheaper

A small plush with a complicated face can cost more than a larger plush with a simple shape. Why?

- small parts are harder to sew consistently

- tight curves and many panels slow down assembly

- face alignment becomes more sensitive (tiny misplacement looks obvious)

“make it smaller to reduce cost,” it sometimes helps, but it can also backfire if the design becomes harder to produce.

Fabric type and stuffing options

Fabric choice impacts both material cost and labor time. Some plush fabrics sew easily and hide seams; others shed, shift, or require extra care. commonly compare velboa/minky/sherpa-type textures and faux fur styles, each with different cost behavior. (Custom Bag Manufacturer)

Stuffing also matters: standard polyfill behaves differently from weighted or structured fills, which can add steps and controls.

Embroidery stitch count vs printing — which is best for budget vs detail

Embroidery cost is often linked to stitch count and color complexity. (Funenjoy: Plush Toy Manufacturing)

Printing is often cheaper for large color areas, while embroidery can feel more premium and durable, especially for facial features that need texture and definition. (Yerong Toy)

A practical mindset:

- If you need fine line detail, embroidery can justify the cost.

- If you need large flat color, printing can control budget.

- Hybrid approaches can be cost-effective if managed well (example: embroidered eyes + printed blush).

Accessories are cost multipliers (clothes, props, zippers, keychains)

Accessories aren’t “small extras.” They are separate mini-supply chains:

- you must source them

- you must install them

- you must QC them

- they can trigger safety or durability expectations depending on market

This is why a plush with a keychain ring or zipper can cost noticeably more than the same plush without it.

Cost Driver Table: What usually moves the needle most

| Driver | Typical effect on price | Why it happens |

|---|---|---|

| More panels / seams | up | slower sewing, more alignment |

| Higher stitch count | up | longer embroidery time (Funenjoy: Plush Toy Manufacturing) |

| Faux fur / special fabric | up | higher waste + careful cutting |

| Clothes / props | up | extra parts + assembly |

| Hardware (keychain/zipper) | up | sourcing + install + QC |

If you’re building a multi-SKU plush series, the smartest way to manage pricing is to standardize fabrics and trims across the set. We’ll cover that in H2-9 with a clear planning method.

How is a plush toy price calculated: what’s in the unit price vs one-time fees (tooling/patterns/molds)?

A professional plush quote separates unit price (materials, labor, QC, packing) from one-time fees (pattern making, embroidery file setup, printing screens, special molds when needed). One-time fees can look painful, but they often reduce bulk risk because they fund correct pattern work and stable artwork execution. To compare quotes, ask for an itemized list and confirm what’s included: packing style, labels, accessories, and whether sample fees can be credited to bulk. (Make My Toy)

Get frustrated when two quotes look totally different. One supplier gives a low unit price but adds “hidden” one-time fees later. Another supplier gives a higher unit price but claims “no extra fees.” The fix is not guessing who’s honest. The fix is forcing the same quote format so you compare apples to apples.

Unit price breakdown (what’s really inside)

Unit price commonly covers:

- fabric + stuffing + thread

- cutting + sewing + stuffing + finishing labor

- standard QC time

- standard packing (often a polybag + carton)

But “standard” varies. One factory’s standard packing includes hangtags and barcode labels; another charges those separately. This is why you must confirm scope.

One-time fees explained (patterns, embroidery files, printing screens, molds)

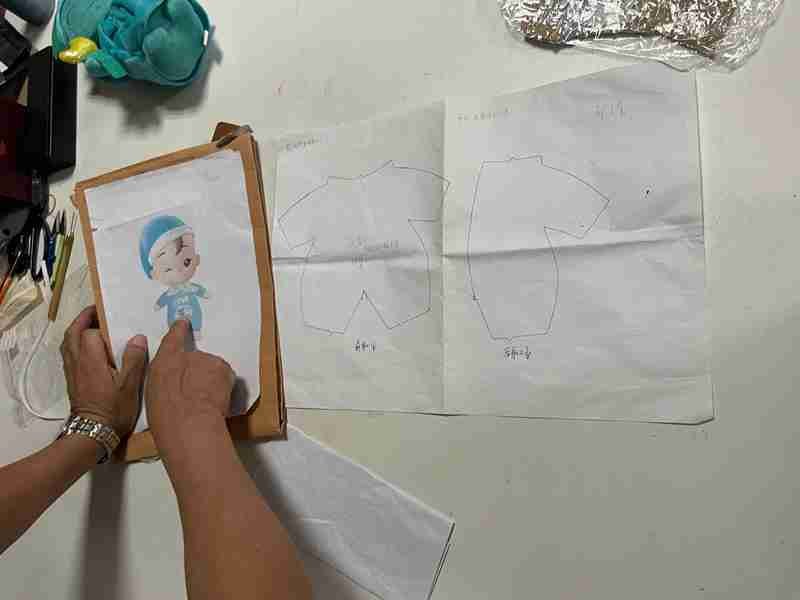

- pattern making (turning your design into cuttable sewable pieces)

- embroidery digitizing (file setup for machines)

- printing screens or setup (depending on technique)

- special molds only when the plush includes molded components or unique parts (less common for standard plush, more relevant for certain accessories)

Sampling is also a one-time cost category in many programs. Some suppliers credit part of sample fees back after bulk orders, but you should confirm this in writing. (Make My Toy)

How to compare quotes fairly (apples-to-apples checklist)

Ask each supplier to confirm:

- Is packing included? Which packing method?

- Are hangtags, barcodes, woven labels included?

- Are accessories included? Which grade?

- Are there any setup fees not listed?

- How many sample rounds are included in the sample fee?

- Is the sample fee creditable to bulk?

Price transparency — what a “good” quote looks like

A friendly quote usually includes:

- unit price by tier (trial vs bulk)

- one-time fee list

- estimated timeline

- payment terms and what triggers the next stage (sample approval, PP sample, bulk start)

Quote Format Table (use this to request a clean breakdown)

| Cost line | Should it be separate? | Why we care |

|---|---|---|

| Unit price | usually yes | compare suppliers fairly |

| Sample fee | yes | sets development budget (Make My Toy) |

| Pattern / artwork setup | yes | explains upfront costs |

| Packaging extras | yes | prevents surprise fees |

| Testing / inspection | yes | market compliance planning |

This format makes pricing feel controllable, not emotional.

Trial order vs bulk order: why is the unit price higher on small runs, and when does bulk pricing become “best value”?

Trial orders cost more per unit because a plush factory still must do the same fixed work—material sourcing, cutting setup, line balancing, QC setup, and packing prep—then spread that cost across fewer units. Bulk becomes “best value” when quantity is high enough to improve cutting efficiency, reduce material waste, and keep workers on the same operation long enough to raise speed and consistency. The right approach is a planned trial → bulk route.

Often hear “small orders are more expensive” and think it’s just a negotiation line. In plush, it’s usually real—and you can see it in simple math.

Trial vs bulk logic — fixed costs spread over quantity

A custom plush program has fixed costs and variable costs.

- Fixed costs: time and coordination that happen even if you make only 100 pcs

- material sourcing and confirmation

- cutting plan setup (pile direction, nesting)

- sewing line setup and method training

- QC standard alignment (defect examples, tolerance rules)

- packing SOP setup (polybag, hangtag placement, carton marks)

- Variable costs: costs that increase per unit

- fabric consumption, stuffing grams

- sewing minutes per unit

- embroidery time per unit (often related to stitch count)

- accessories and packaging materials

When you order 300 pcs, the fixed part is spread across 300. When you order 3,000 pcs, it’s spread across 3,000. That’s the heart of trial vs bulk pricing.

Here’s a example (numbers are not a promise—just a way to understand the logic):

| Cost type | Example cost | If you order 300 pcs | If you order 3,000 pcs |

|---|---|---|---|

| Fixed setup work | $900 | $3.00/unit | $0.30/unit |

| Variable production | $4.20/unit | $4.20/unit | $4.20/unit |

| Estimated unit price | — | $7.20/unit | $4.50/unit |

That difference is why “low MOQ” can be real but feel pricey.

Best MOQ strategy for new customer (how to start small without paying “worst-case pricing”)

New customer often need a trial run for a launch, a crowdfunding test, or first retailer feedback. That’s normal. The smarter goal is not “cheapest unit price today.” The smarter goal is a pricing ladder you can actually climb.

A practical strategy:

- Start with one core style (not 4–6 styles at once)

- Keep the first run’s options tight: fewer colors, fewer accessory variations

- Use stock fabric colors if possible (avoid custom dye for the first test)

- Make the first order “clean” for production: stable pattern, stable face method

- Plan the second order early so the factory can quote a realistic bulk tier

This is also where “shared components” help: if your series uses the same eye model, the same label, the same hangtag format, the same polybag size, you can reduce the minimum pressure on accessories.

When bulk pricing becomes best value (breakpoints that matter)

In plush, bulk value improves when:

- fabric can be purchased in better tiers (lower unit fabric cost)

- cutting waste drops because layout becomes efficient

- sewing becomes faster because workers repeat the same operation

- QC improves because the line stabilizes (fewer rework loops)

The “breakpoint” is not one magic quantity for every plush. It depends on:

- plush size and number of panels

- embroidery vs printing decision

- accessories and packaging complexity

- how many SKUs you split the order into

When a trial order is still the right move

Trial orders make sense when:

- you’re validating market demand

- you need content (photos, reviews, unboxing) before scaling

- you’re testing a new character series

- you want to confirm feel, face alignment, and packaging method first

The risk is doing a trial that’s too complicated: too many SKUs, too many fabrics, too many accessories. That usually creates “trial pain” without giving you clean data.

If you want a low-risk start: share your SKU plan and target quantity range, and Heyzizi can recommend a trial structure that keeps unit pricing rational while protecting the path to bulk.

What are sampling cost factors for custom plush: how much, why it varies, and is the sample fee deductible?

Sampling fees vary because samples include real development work: pattern making, embroidery/printing setup, material sourcing, and multiple build-and-revise cycles. A simple plush sample can be cheaper; a plush with clothing, hardware, special fabrics, or complex embroidery usually costs more and takes longer. Sample fees are sometimes creditable against bulk, but should confirm the rules in writing—especially what counts as “bulk,” and how many sample rounds are included.

Sampling either build confidence—or lose control of budget. The key is to stop treating sampling as a single event (“make me a sample”) and treat it as a process with stages, decisions, and proof points.

Sample stages — proto vs revision vs PP sample (what each stage proves)

A practical plush sampling route often looks like this:

- Proto sample

- proves: basic shape, proportions, construction feasibility

- common issues found: shape mismatch, panel size errors, face layout not realistic

- Revision sample(s)

- proves: face method (embroidery/printing), accessory integration, stuffing feel

- common issues found: embroidery placement drift, accessory look/fit problems, “feel” not matching target

- PP sample (pre-production sample)

- proves: bulk-ready standard using intended materials and near-bulk methods

- common issues found: small details that can drift in bulk (seam allowance, reinforcement points, packaging deformation)

If a supplier skips the PP stage on a complex plush, you may save time now—but risk more cost later.

Sampling cost drivers (why one sample can be “cheap” and another is “not cheap”)

Sampling cost usually increases when you add:

- more pattern parts (more panels = more pattern work + more sewing time)

- complex curves or tiny parts (higher skill requirement and more rework risk)

- heavy embroidery (more digitizing and machine time)

- special fabrics (faux fur, long pile, tricky backing)

- accessories (clothing sets, props, keychains, zippers, magnets where allowed)

- custom packaging (retail box, inserts, special hangtags)

A useful way to discuss sampling is to ask the factory to list “what makes this sample hard.” If they can’t explain it, the project may get surprises later.

Sample fee deduction — when it’s deductible and what to confirm in the PO

Some factories credit part of sample fees after you place bulk. That can be fair, because development effort supports the mass order. But you should confirm:

- Is the sample fee creditable? Full or partial?

- What order quantity qualifies as bulk?

- Does the credit apply to the first bulk PO only?

- Does it cover multiple SKUs or only the same style?

- How many revision rounds are included?

- What is considered a “new sample” vs a “revision”?

This prevents “I thought it was included” misunderstandings.

How to shorten sampling cycles (without sacrificing quality)

If speed matters, the fastest wins are usually on the customers side:

- provide clear reference images (front/side/back if possible)

- confirm target size and a “must keep” feature list

- choose face method early (embroidery vs printing)

- limit SKUs during sampling (don’t sample 6 variants at once)

- give feedback in one clean list, not scattered messages

- confirm file versions (avoid “old art” being used)

Sampling planning table (simple but powerful):

| What you decide early | What it saves | Why it matters |

|---|---|---|

| Face method | days | prevents redo of embroidery/printing setup |

| Accessory list | days + money | avoids sourcing changes mid-sample |

| Fabric direction | days | reduces cutting mistakes and rework |

| Packaging method | rework | prevents deformation issues later |

If you want Heyzizi to quote sampling realistically, send your design references and tell us your target market and deadline. We’ll propose a sampling route that fits your launch plan.

How long does sampling and production take, and which decisions speed up (or slow down) lead time?

Sampling and production timelines depend on design complexity and material readiness. A typical route is RFQ review → sample rounds → approval/PP sample → bulk production → packing → shipment. Lead time slows down most often بسبب color matching, custom fabric sourcing, accessory procurement, and peak-season capacity. You can speed things up by reducing SKUs, choosing stock materials, locking artwork versions early, and approving a clear spec pack before bulk starts.

Lead time is where plush projects get emotionally stressful. We often plan marketing first and production second. Then a small delay—like waiting for a fabric color confirmation—pushes everything.

Instead of chasing “fast,” plan “controlled.” Controlled timelines are more predictable, which is what you really need if you’re launching a brand or delivering to retail.

Typical timeline — RFQ → sampling → approval → bulk → shipment

A realistic plush timeline has stages, not one date:

- RFQ review and feasibility (confirm size, face method, accessories, packing)

- Sampling (proto + revisions)

- PP sample (bulk-ready standard)

- Bulk production (cutting → sewing → stuffing → finishing)

- Packing and pre-shipment checks

- Shipment scheduling

Even if your supplier is fast, you still need time for feedback and approvals. That’s why who respond quickly often get better delivery outcomes.

What delays plush lead time most (the real list)

Common delay sources:

- color matching: matching plush fabric shades to a reference can take time

- custom dye lots: if you need a custom color, fabric lead time expands

- accessory sourcing: eye models, custom woven labels, keychains, zippers

- packaging sourcing: custom printed boxes or inserts

- artwork changes: “one more tweak” resets embroidery or printing prep

- peak season capacity: factories schedule larger bulk orders first

The key point: many delays come from decisions changing midstream, not from slow sewing.

Rush fees vs planning — when speed changes total cost

If you truly need rush production, cost can rise because:

- material must be sourced faster (higher purchasing cost)

- lines must be rearranged (efficiency drops)

- overtime increases (labor cost rises)

- QC pressure increases (risk goes up if the process isn’t disciplined)

Sometimes rush is worth it. Sometimes it’s cheaper to launch two weeks later than to pay rush costs and risk quality drift.

Lead time risk planning for new customer (buffer strategy)

If you’re new, assume you’ll need at least one revision cycle. Build buffer around:

- sample feedback time (you + your team + your brand partners)

- material confirmation time

- packing design approval time (if retail packaging is needed)

- shipping variability

A simple buffer approach many use:

- buffer 5-10 days for sampling decisions

- buffer 3–14 days for materials and accessories

- buffer for shipping based on your route and season

The “speed levers” you control (and they’re not complicated)

Fast decisions that usually save the most time:

- lock the face method early

- limit the number of SKUs for the first order

- use stock colors for the first run

- confirm packaging method early

- approve a clear spec pack before bulk starts

If you send Heyzizi your target launch date, quantity range, and SKU plan, we can recommend a timeline that fits reality—so you don’t get trapped by optimistic guesses.

Which quoting inputs should provide to get an accurate MOQ & price: spec pack vs reference photos vs target market?

Accurate plush pricing depends on clear inputs. At minimum, factories need size, quantity range, fabric direction/type, face method (embroidery vs printing), accessories, and packaging. Target market (kids vs general) matters because it affects testing, QC intensity, and documentation. A clean spec pack gives the fastest accuracy, but good reference photos plus clear priorities can also work if expectations are aligned early.

Most pricing problems start before a quote is ever issued. Send “inspiration photos,” factories guess, and the first price becomes a placeholder—not a decision tool. To avoid re-quotes and surprise add-ons, treat RFQ inputs as a cost-definition exercise.

RFQ must-haves (what actually changes price)

Friendly RFQ doesn’t need to be fancy, but it must be specific where it counts:

- Size (finished height/length and tolerance if known)

- Quantity range (trial qty + expected bulk tier)

- Fabric (type, pile direction, stock vs custom color)

- Face method (embroidery vs printing, or hybrid)

- Accessories (eyes/nose models, clothes, props, keychains, zippers)

- Packaging (bulk polybag vs retail-ready with hangtag/box)

If any of these are missing, factories fill the gap with assumptions—and assumptions change prices later.

Spec pack vs reference photos — which is better?

- Spec pack (best accuracy): defines size, materials, workmanship, placement, tolerances. Pricing is faster and more stable.

- Reference photos (works for early stage): good if you add notes like “similar size,” “same fabric type,” “face embroidery only,” “no accessories.”

A practical approach: start with references to test feasibility, then convert to a simple spec pack before bulk.

Target market matters (kids vs general)

Pricing is affected by where and how the plush will be sold:

- Children’s markets can trigger stricter QC, documentation, and testing expectations.

- General gifting may allow lighter controls.

- Promotional giveaways often prioritize unit price and speed over retail packaging.

Be clear early. Changing market intent later (e.g., “we decided it’s for kids”) usually adds cost and time.

Who pays for what — avoid hidden costs

Clarify early:

- sample fees (how many rounds included?)

- testing (in-house checks vs third-party labs)

- inspection (factory QC vs third-party)

- packaging extras (hangtags, barcodes, inserts)

- shipping terms (EXW/FOB/others)

What to ask a manufacturer (use question-led checks)

Ask questions that force scope clarity:

- What is included in unit price?

- Which items are extra?

- How long does sampling take by stage?

- Do sample fees credit to bulk?

- Is packaging included?

- Are there accessory minimums that affect MOQ?

If a factory answers these cleanly, pricing becomes predictable—not emotional.

How do quality requirements change pricing: AQL inspection, defect prevention, and packaging standards?

Higher quality standards raise cost because they add labor time, controls, and sometimes better materials. AQL inspections, defect-prevention steps, needle control, and stronger packaging all increase unit cost—but often reduce total program cost by lowering rework, returns, and brand risk. The key is aligning QC level with market risk, not overbuilding controls where they don’t add value.

“Quality” sounds abstract until you connect it to cost. In plush, quality cost shows up as time: more checks, more documentation, more careful handling. The mistake make is either demanding everything (overpaying) or cutting everything (paying later).

QC level vs unit price — what actually changes

Raising QC standards can add:

- more in-line inspections (labor minutes)

- additional verification steps (first-piece, patrol checks)

- needle control discipline and recordkeeping

- slower output to maintain consistency

- higher-grade accessories or reinforcements

Each item nudges unit price, but they also reduce the chance of bulk failure.

AQL inspection and third-party checks

AQL inspections cost money, but they serve a purpose:

- independent verification for bulk shipments

- a shared language between customers and factory

- protection for reorders and dispute resolution

AQL makes the most sense for:

- retail programs

- private label lines

- larger shipments where risk exposure is higher

Packaging standards — cost vs damage reduction

Packaging is often underestimated. Plush can deform, crease, or lose shape:

- bulk packing is cheaper but risks deformation

- retail-ready packing costs more but protects presentation

Better packaging can reduce:

- warehouse rejections

- customer complaints

- rework before selling

Quality cost vs failure cost

A useful way to think:

- QC cost is predictable and controllable

- failure cost is unpredictable and reputational

If your plush is part of a brand story, content launch, or retail shelf, controlled QC often pays for itself.

QC Cost Perspective Table

| QC choice | Adds unit cost? | Reduces risk of |

|---|---|---|

| In-line checks | ✅ | seam drift |

| Needle control | ✅ | safety incidents |

| Better packaging | ✅ | deformation claims |

| Third-party inspection | ✅ | shipment disputes |

How to negotiate plush pricing with a factory without sacrificing quality: which levers work best?

Effective plush price negotiation focuses on design and planning levers, not squeezing labor. The strongest levers are standardizing materials, reducing embroidery stitch count, simplifying accessories, and planning multi-SKU series with shared components. Forecasting reorders and locking workmanship standards also unlock better pricing tiers without creating quality shortcuts.

Good negotiation doesn’t feel aggressive. It feels technical. You’re not asking the factory to “try harder.” You’re removing friction from the build.

How to plan pricing for a multi-SKU plush series

Multi-SKU series fail when every SKU is treated as unique. They succeed when SKUs share a backbone:

- same fabric type and color palette

- same eye/nose models

- same label and hangtag format

- same packaging size

Then you vary:

- embroidery details

- accessories (kept modular)

- color accents

This lets factories combine purchasing and stabilize lines—lowering unit cost across the set.

Negotiation levers that work

Levers that usually help:

- reduce embroidery stitch count without losing expression

- switch some details from embroidery to printing

- standardize trims across SKUs

- simplify clothing pieces (fewer panels, fewer layers)

- plan quantities by tier (trial → reorder → scale)

Levers that usually don’t work:

- pushing labor price below realistic levels

- demanding ultra-low MOQ with full customization

- skipping PP samples to “save time”

Reorder strategy — where real savings live

The best prices usually appear on the second or third order, not the first. Why?

- materials are already approved

- patterns are proven

- workers are familiar

- QC standards are locked

Ask for tiered pricing tied to forecast quantities. Even if you don’t commit, it frames a partnership mindset.

Avoid “cheap sample, expensive bulk” traps

Protect yourself by:

- approving a PP sample built like bulk

- locking workmanship standards

- documenting change control (what requires re-approval)

This keeps bulk pricing honest and repeatable.

If you want predictable pricing—not surprises—the fastest path is a clear plan. Share your plush type, target quantity, SKU plan, and market. We’ll respond with a realistic MOQ strategy, pricing logic, sampling route, and timeline—so you can launch with confidence and scale without rework.

📩 Contact Heyzizi for custom plush manufacturing:

Email: info@heyzizi.com

FAQs — MOQ & Pricing for Custom Plush (Cost Drivers, Trial vs Bulk, Sampling)

What is the MOQ for custom plush toys, and why do different factories give different numbers?

MOQ for custom plush is usually the minimum quantity a factory can run per design (per character / per size / per colorway) without losing money on setup work. The reason you see different MOQs is that each factory has different realities: their fabric sourcing channels, line scheduling, how they define a “new style,” and whether they have stock fabric options ready. Some factories quote MOQ based on sewing capacity only, while others include upstream supplier minimums (fabric yardage, eyes/noses, labels, packaging). That’s why one factory can say “MOQ 300” and another says “MOQ 1,000”—they may be counting different constraints.

A reliable way to compare is to ask: Is MOQ per style or total? Is MOQ affected by custom-dyed fabric or special accessories? and Can you consolidate multiple SKUs using the same fabric and trims? If you tell Heyzizi your SKU plan, target market, and whether you can use stock colors, we can propose a realistic MOQ structure that doesn’t trigger surprise add-ons later. Email info@heyzizi.com.

Why is the unit price higher for a trial order, even if the plush looks simple?

Trial order pricing is higher because plush production has fixed work that doesn’t shrink much when the quantity is small. Even for a “simple” plush, the factory still has to do material confirmation, cutting layout planning (pile direction matters), line setup, QC alignment, and packing preparation. Those hours are real. When you produce 200–500 units, those fixed hours get spread across fewer pieces, so the cost per unit climbs.

This is also why “low MOQ” is possible but often not “cheap MOQ.” The smartest customer mindset is to treat trial production as a data-gathering run: confirm feel, face alignment, packaging, and customer response—then step into bulk pricing on reorder. If you want, we can quote a two-stage plan: trial tier + forecasted bulk tiers, so you can budget your launch and know what your unit cost can become once you scale. Send your target qty range to info@heyzizi.com.

What factors drive plush toy pricing the most (the real cost drivers)?

The biggest price drivers in plush are usually not “mystery fees.” They’re predictable engineering choices:

- Size + stuffing weight (bigger plush uses more fabric and fill)

- Pattern complexity (more panels, tighter curves, more sewing minutes)

- Face method: embroidery stitch count vs printing (embroidery time can dominate)

- Fabric type (special faux fur, long pile, tricky backing increases waste and labor)

- Accessories (clothes, props, zippers, keychains, woven labels—each adds sourcing + operations)

- Packaging requirements (retail-ready packing costs more than bulk polybag/carton)

A small plush can cost more than a larger one if it has complex embroidery, many parts, or multiple accessories. If you want the best value, focus on simplifying operations (fewer panels, fewer accessory steps) and standardizing fabrics/trims across SKUs. If you share your design sketch or reference image, Heyzizi can highlight which elements are cost multipliers and suggest alternatives that keep the character look while controlling price. Email

How can I estimate price impact when I change size, embroidery, or accessories?

We often ask “If we make it 2 inches smaller, how much cheaper?” The honest answer is: it depends on which part of the cost is dominating. In plush, labor minutes and embroidery time can dominate more than fabric. So sometimes a size change helps, sometimes it barely moves price.

Here’s a practical “price impact map” you can use:

| Change | Typical impact on price | Why |

|---|---|---|

| Reduce size slightly | Low–Medium | may reduce fabric/fill, but labor time may stay similar |

| Reduce panel count | Medium–High | fewer sewing operations = faster line speed |

| Reduce embroidery stitch count | High | less machine time and setup complexity |

| Switch some embroidery to printing | Medium–High | lowers stitch time; printing can be cheaper for large color areas |

| Add clothing/props | High | extra patterns + sewing + QC |

| Add keychain/zipper hardware | Medium–High | sourcing + installation + QC |

If you want a fast, accurate estimate, send Heyzizi your “before/after” idea (like embroidered face vs printed face, or with clothes vs no clothes) and we’ll give you a grounded cost-direction answer before you spend time sampling. Email info@heyzizi.com.

What is included in the unit price, and what should be listed as separate fees?

A professional plush quote should clearly separate unit price from one-time fees and optional services. Unit price typically includes: fabric, stuffing, sewing labor, basic finishing, basic QC, and basic packing (often polybag + carton). Separate fees can include: pattern making, embroidery digitizing, printing setup, special molds (if needed), custom packaging printing, lab testing, third-party inspection, and sometimes complex accessory sourcing.

The danger is when quotes are not comparable: one supplier hides setup work inside unit price, another breaks it out. Neither is automatically “better”—but you must compare the full program cost.

Use this checklist to force clarity:

| Line item | Ask “is it included?” | Why it matters |

|---|---|---|

| Packaging type | yes | retail packing changes cost a lot |

| Accessories grade | yes | cheap hardware can create returns |

| Sample fee policy | yes | affects your dev budget |

| Testing/inspection | yes | can be required by your market |

If you email Heyzizi your target market + packaging needs, we can quote with a clean structure so your finance team can approve faster. info@heyzizi.com

How much does a custom plush sample cost, and why does sampling pricing vary so much?

Sampling costs vary because sampling is not “one product.” It is development work: translating artwork into a buildable plush, making patterns, setting embroidery/printing files, sourcing materials, then revising until the product matches your brand expectations. A simple sample with basic fabric and minimal accessories can be straightforward. A complex character with clothes, props, special fur, multiple embroidery zones, or strict brand color standards will take more time and often multiple rounds.

Sampling cost typically increases with:

- pattern complexity (more parts, more alignment points)

- embroidery stitch count and density

- special fabrics (long pile / faux fur / tricky backing)

- accessories (keychain, zipper, clothing sets)

- custom packaging mockups (if required early)

If you want to control sampling cost, the best move is to send clear references and confirm what is “must match” vs “nice to have.” Heyzizi can also propose a sampling route (proto → revision → PP sample) so you don’t pay for unnecessary rework. Email info@heyzizi.com.

Is the sample fee refundable or deductible from bulk production?

Sample fee policies vary by factory, and misunderstandings are common. Some factories credit a portion of sampling cost into the first bulk order because the development work supports production. Others treat sampling as a standalone service because it consumes skilled labor and materials whether you order bulk or not.

The best practice is to confirm these points in writing (PO/email):

- Is the sample fee creditable? full or partial?

- What quantity qualifies as bulk? (per style or total?)

- How many revisions are included?

- What changes count as a “revision” vs a “new sample”? (size change, fabric change, face method change)

- Does the credit apply to the first bulk PO only?

If you want a policy that feels fair and predictable, tell Heyzizi your expected order path (trial qty, reorder qty). We’ll recommend a sampling plan and a documentation approach that keeps the relationship clean. Email info@heyzizi.com.

Can any character artwork be made into plush?

Most character artwork can be translated into plush, but not all artwork translates cleanly without design adjustments. Plush is 3D, compressible, and stitched—so extremely thin lines, complex gradients, tiny facial features, or high-detail textures may require trade-offs. The biggest cost jumps usually happen when insist on keeping every detail exactly as a flat drawing.

Cost-impacting translation choices include:

- Embroidery vs printing for face detail (high stitch count raises cost)

- adding layered appliqué to mimic complex shapes

- creating clothing pieces instead of printed clothing

- using long pile fur to mimic texture (increases waste and labor)

- adding rigid elements or hardware for “props”

A strong factory will give you options: “If we keep this exact, cost goes up X direction; if we simplify this part, you keep the character but control price.” If you send Heyzizi your artwork and target size, we can recommend the best production translation—without losing the personality. Email info@heyzizi.com.

How do I plan pricing for a multi-SKU plush series ?

A multi-SKU series becomes expensive when every SKU is treated as unique—different fabrics, different trims, different packaging sizes. The smarter approach is to design a “shared backbone” so the factory can purchase and produce efficiently. Use the same base fabric, same eye/nose model, shared label formats, and shared packaging sizes—then vary small elements (embroidered expression, accent colors, modular accessories).

One character vs series collection is a brand question and a cost question:

- One hero character builds recognition faster if you push distribution and content.

- A series can build faster if you sell as a collectible set and share production components across SKUs.

Here’s a practical planning table:

| Strategy | Best for | Pricing advantage |

|---|---|---|

| One hero character | first launch, limited budget | simplest sourcing + lowest complexity |

| Series with shared parts | gift shops, retail sets | shared material buys reduce cost |

| Series with unique builds | premium collectors | higher price, higher dev cost |

If you share your series plan (how many SKUs, what differs), Heyzizi can suggest how to structure it so the series feels rich but the pricing stays controllable. Email info@heyzizi.com.

Risk checklist for licensed IP plush programs: what can increase cost or delay fast?

Licensed IP plush programs are highly doable, but they have extra cost and time risk because approvals are layered. The biggest risk isn’t production—it’s approval loops and scope creep. Common triggers:

- licensor requires strict color standards and proofing

- packaging and hangtags must be approved

- embroidery files and placement proofs require sign-off

- safety labeling and compliance documentation must match licensor rules

- royalty reporting or special packaging inserts add workflow

A practical risk checklist:

- Confirm what needs approval: sample, packaging, labeling, carton marks, online photos

- Confirm approval timing: who signs off and how long it usually takes

- Lock version control: artwork file version, embroidery file version, PMS references

- Plan buffer time for at least one revision cycle

If you’re running a licensed project, tell Heyzizi the approval structure and deadlines. We can build a sampling and documentation route that keeps approvals organized and prevents costly last-minute changes. Email info@heyzizi.com.

Best MOQ strategy for new customer: how do I start small but still get a fair price?

New customer often feel trapped: they want low MOQ, but they don’t want the “worst-case” unit price. The best strategy is to start small in a controlled way, not in a complicated way. Keep the first run tight: one core size, limited colors, minimal accessories, and stock materials where possible. Then plan the reorder tier early so the factory can quote realistic bulk pricing.

A good “starter plan” looks like:

- Trial: 1 style, 1–2 colorways, simplest packaging

- Reorder: same base build, add variations after the backbone is stable

- Scale: tiered pricing based on forecast, not guessing

This approach reduces development cost and makes your first bulk reorder smoother. If you send Heyzizi your target quantity and launch channel (online, retail, souvenir, promo), we can recommend a starter plan that balances cost and speed. Email info@heyzizi.com.

How long does sampling and bulk production take, and which decisions slow it down most?

The most accurate timeline is a staged timeline: RFQ → proto sample → revision → PP sample → bulk → packing → shipment. Lead time slows down most when decisions are not locked early. Common delays include custom dye fabric, accessory sourcing (custom eyes, keychains, zippers), embroidery file rework, and packaging approvals—especially for licensed programs or retail packaging.

The fastest ways to keep timeline predictable:

- lock face method early (embroidery vs printing)

- reduce SKUs during sampling (don’t sample 6 variants at once)

- choose stock materials for the first run

- give feedback in one organized list

- confirm packaging method early

If you tell Heyzizi your deadline and which parts are flexible, we can propose a timeline that fits reality and avoids risky “rush mode.” Email info@heyzizi.com.

How can I negotiate pricing without reducing quality?

The best price negotiation in plush is not squeezing labor—it’s removing complexity. Levers that actually work:

- reduce embroidery stitch count while keeping expression

- standardize fabrics and trims across SKUs

- simplify clothing patterns (fewer panels/layers)

- modularize accessories (optional add-ons)

- forecast reorders and request tiered pricing

Levers that usually backfire:

- demanding ultra-low MOQ with full custom fabric + full accessories

- skipping PP samples to “save time”

- changing artwork repeatedly after sampling started

If you want, Heyzizi can give you a “cost-down options list” for your specific design, so you choose what to keep premium and what to simplify.

What information should I send to get an accurate quote quickly (and avoid re-quoting)?

To quote plush correctly, the factory must understand what’s being built and what standard you expect. The fastest quote happens when you provide:

- size and target feel (soft, firm, weighted)

- quantity range (trial + expected bulk)

- artwork + reference images (front/side/back if possible)

- face method preference (embroidered vs printed)

- accessories list (clothes, props, keychain, zipper, labels)

- packaging needs (bulk vs retail-ready)

- target market (kids vs general) and compliance expectations

- delivery window

If you don’t have all details, send what you have and say what’s undecided. A good manufacturer will propose options and explain cost impact. Heyzizi can respond with a structured quote and a sampling route so your team can decide faster. Email info@heyzizi.com.