A Plush Toy OEM Factory Focused on Process and Quality

Direct Plush Toy Manufacturing for Brands and OEM Buyers

We are a plush toy manufacturer specializing in OEM and custom production for brands, IP owners, retailers, and promotional clients. Our factory focuses on controlled manufacturing processes, stable quality standards, and long-term cooperation rather than short-term trading.

All plush toys are developed and produced in-house, allowing us to manage each step from sampling to mass production with clear communication and reliable execution.

Why Buyers Work With Our Plush Toy Factory?

A Plush Toy Factory Focused on OEM Manufacturing and Quality Control

Buyers choose to work with us because we operate as a direct plush toy factory, not a trading intermediary. Our focus is on OEM manufacturing, controlled production processes, and consistent quality rather than short-term transactions.

By managing development, production, and quality control in-house, we provide clearer communication, better process visibility, and more reliable execution from sampling to mass production. This structure helps brands reduce risk and achieve stable, repeatable results.

Why Work Directly With Our Factory

Working directly with our plush toy factory offers practical advantages for OEM buyers:

Direct factory communication

Communicate with development and production teams without intermediaries.

Clear development process

Structured workflows from sample development to mass production.

Stable production capacity

In-house manufacturing ensures consistent scheduling and output.

Controlled quality standards

Quality control is integrated into every production stage.

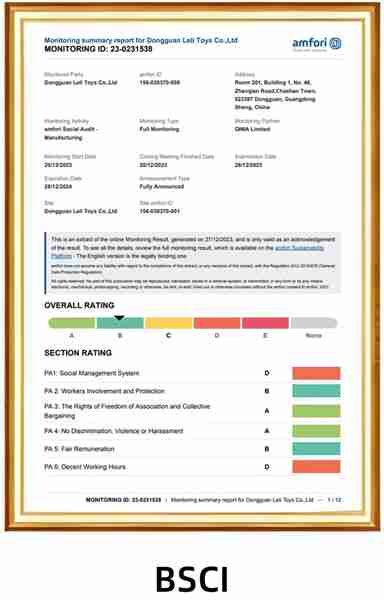

Compliance support

EN71 / CE for UK & EU markets, ASTM F963 for the US market, CPSIA upon request.

Long-term OEM & ODM cooperation

Built for brands seeking stable and repeatable plush manufacturing.

Who We Are as a Plush Toy Manufacturer?

We are an OEM plush toy manufacturer experienced in developing and producing standard plush toys, custom character plush, promotional items, and giant plush products.

Our team works closely with brands, IP owners, retailers, and promotional clients. Every project follows a structured manufacturing approach designed to support both sample development and scalable mass production.

What We Do as an OEM Plush Factory

Our factory supports the full plush toy manufacturing process, including:

- Custom plush development and sampling

- Pattern making and structure engineering

- In-house cutting, sewing, and stuffing

- Hand finishing and appearance control

- Multi-stage quality inspection

- Packaging and shipment preparation

Approved samples serve as the technical and quality reference throughout mass production, ensuring consistency between samples and bulk orders.

How We Control Quality Throughout Production

Quality control is not a single inspection. It is a system applied throughout material selection, production, and finishing.

Our quality control process includes material inspection, in-line production checks, needle and metal safety inspection, final appearance inspection, and pre-shipment verification. Issues are identified early and corrected immediately to prevent defects from accumulating.

This structured approach supports safety, durability, and consistent quality, especially for plush toys intended for children and regulated markets.

Our Plush Toys Range

A selection of plush toy categories we commonly manufacture for OEM and brand clients.

Our factory manufactures a wide range of custom plush toys for OEM and brand clients across different industries.

Rather than fixed products, these categories represent the types of plush projects we commonly develop and produce, from character-based designs to large-scale promotional and retail plush.

Each category reflects our experience in custom development, process control, and stable mass production, allowing buyers to quickly identify whether their project fits our manufacturing capabilities.

Custom Character Plush

Custom-made plush toys based on IP characters, mascots, and original artwork, developed for OEM and licensed production.

Yours Animal Plush Toys

Classic animal plush toys produced for retail and wholesale distribution, with custom materials and design variations.

Retail Plush Collections

Plush toy series developed for retail stores and gift shops, focusing on consistent quality and repeatable production.

custom Giant Plush Toys

Large-scale plush toys requiring reinforced structure, controlled stuffing, and durability, commonly produced for events and display.

Promotional Plush Toys

Plush toys designed for marketing campaigns, giveaways, and brand promotions, optimized for bulk orders and event use.

Custom Plush Mascots

Wearable or display plush mascots developed for brand identity, exhibitions, and promotional use, with custom sizing and structure.

Seasonal & Holiday Plush

Plush toys developed for seasonal campaigns and holiday collections, such as Christmas, Halloween, and special events.

Plush Keychains & Mini Plush

Small-size plush products designed for promotional bundles, accessories, and gift sets, suitable for large-volume production.

OEM Exclusive Plush Projects

Fully customized plush projects developed under OEM or private-label agreements, from sample development to mass production.

Educational & Story Plush

Plush toys designed for educational brands, books, and storytelling projects, with emphasis on safety and consistency.

Custom Soft Doll Plush

Human-style plush dolls developed for retail and branded collections, focusing on facial details and sewing accuracy.

Custom Plush Sets & Series

Multiple-design plush sets produced as series collections, requiring color control and batch consistency.

Inside Our Plush Toy Factory

Our Production Capabilities

We believe transparency builds trust. By showing real production environments, buyers can better understand how plush toys are manufactured in our factory, rather than relying on descriptions alone.

Our factory videos and photos present actual sewing lines, stuffing operations, in-line quality inspections, needle detection, and packing processes. These visuals reflect our daily manufacturing workflow, helping buyers evaluate our production capability, process control, and working standards with confidence.

Selecting Raw Materials

Customer Sample Production Room

Selecting Raw Materials

Mechanical laser cutting

Batch computer embroidery

Sewing Lines in Operation

In-Line Quality Inspection

Stuffing Process Control

Hand Stitching & Closure Finishing

Shape Adjustment & Surface Finishing

Needle Detection & Metal Safety Inspection

Packing & Carton Preparation

Cooperating Brands Trusted

We cooperate with brands across gift, retail, publishing, and promotional industries. Many of our partnerships are long-term and built on consistent quality, clear processes, and reliable delivery.

Rather than focusing on volume, we focus on stable cooperation and repeatable manufacturing results.

Client Testimonials

800+ brand Clients Trust heyzizi

Our Story-From 2000 To Today

2000 – Jundong established in Guangdong

2005 – Began international export operations

2010 – Expanded to EU, US, and Middle East markets

2015 – Launched in-house design and sampling center

2020 – Upgraded automation and ERP system

2025 – Servicing 800+ global B2B clients

Make a Sample Before Mass Production

Before moving into mass production, sample development allows verification of structure, materials, workmanship, and quality standards.

If you are planning a custom plush project or evaluating a reliable plush toy factory, we welcome you to discuss your requirements with our team.

- info@heyzizi.com

- (+86)13717153084