IP Character Plush Development

Learn how to turn 2D character art into accurate 3D plush, control face accuracy, approve a golden standard, manage licensed IP risk, and scale production.

Expect actionable guides on custom plush toy manufacturing, spec confirmation, bulk consistency, defect prevention, labeling & barcode handling, and EN71/ASTM planning.

We write with real procurement use in mind: checklists, tables, approval points, and “what can go wrong” notes.

If you’re preparing an RFQ, our templates help you send complete specs and get faster, more accurate quotes.

These featured guides cover the decisions that shape cost, lead time, and bulk consistency, helping you move from RFQ to sampling and mass production with fewer revisions and fewer surprises.

plush fabric options, handfeel targets, color matching

embroidery vs printing, woven labels, hangtags, barcodes

defect prevention, inspection checkpoints, needle control options

anti-deformation packing, carton marks, shipping modes

cost drivers, trial vs bulk logic, sampling cost factors

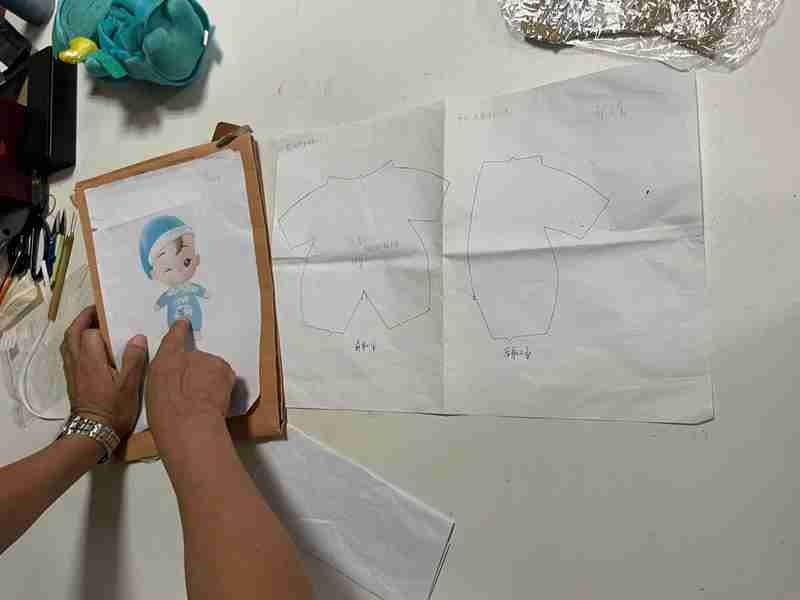

2D to 3D translation, face accuracy, golden standard

market/age grade planning, EN71/ASTM basics

This feed highlights our newest guides and how-to posts. We write titles around real buyer searches, and we design each article to deliver something usable—checklists, tables, approval points, and risk notes—so your team can move faster.

Learn how to turn 2D character art into accurate 3D plush, control face accuracy, approve a golden standard, manage licensed IP risk, and scale production.

Most plush projects don’t fail because the character is “not cute enough.” They fail because the brand system breaks in real life: the logo looks great on screen but turns stiff on plush fabric, the woven label scratches, the hangtag tears off in transit, the barcode won’t scan at the warehouse, or the cartons arrive with missing marks and your 3PL can’t sort SKUs fast. That’s when a simple plush order turns into late launches, rework, and extra costs you never planned for.

Plan plush toy safety by market (US/EU/UK), age grade, small parts, EN71/ASTM basics, and QC steps that reduce recall risk before bulk.

guide to anti-deformation packing, carton marks, barcodes, and shipping modes for custom plush—reduce damage, delays, and relabeling.

Quality Control for Custom Plush: Defects & Needle Control

Learn plush QC defect prevention, inspection checkpoints, seam strength control, and needle control options to reduce recalls and keep bulk consistent.

Understand MOQ, plush pricing drivers, and sampling costs. Learn trial vs bulk math, multi-SKU planning, and how to get accurate quotes.

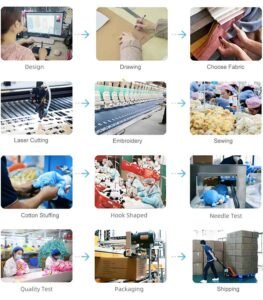

Custom plush toy manufacturing works best when buyers treat it like a controlled process, not a one-time purchase. A reliable factory starts with a clear RFQ, then converts artwork into a buildable pattern, confirms materials, and produces samples for approval. Once the golden sample is signed off, bulk production follows locked specs, QC checkpoints, and packaging rules to keep consistency. Planning early for age grade, safety, and labeling reduces rework and speeds delivery.

Many projects slow down because key details are missing—size, fabric, packaging, target market, or branding method. That leads to slower quotes, repeated sample revisions, and uncertain timelines. Our RFQ checklist helps you send complete specs in one go, so we can respond with a practical plan.

What you’ll receive

If you prefer email communication, you can send your RFQ and artwork to info@heyzizi.com

Your mascot is knocking on our door asking to be made!

Let’s Create Something Adorable Together!

Start Your Custom Plush Project – It Only Takes 59 seconds!

If you prefer direct communication, you may also reach us through the following channels, Email: info@heyzizi.com

Your Mascot Is Knocking On Our Door Asking To Be Made!

Let’s Create Something Adorable Together!

Start Your Custom Plush Project – It Only Takes 59 Seconds!