What Happens From RFQ to Bulk Production, How Long It Takes, and How to Choose the Best Manufacturer?

Most customer think plush production is “send artwork → get a sample → place an order.” That’s how projects get delayed, quoted wrong, and reworked twice. Plush looks simple, but it’s a product that mixes soft materials, handmade sewing, expression accuracy, and channel requirements (retail packaging, safety tests, barcodes, fulfillment labels). One small gap—like an unclear face method, missing accessory spec, or loose size tolerance—can ripple through sampling, pricing, and bulk consistency.

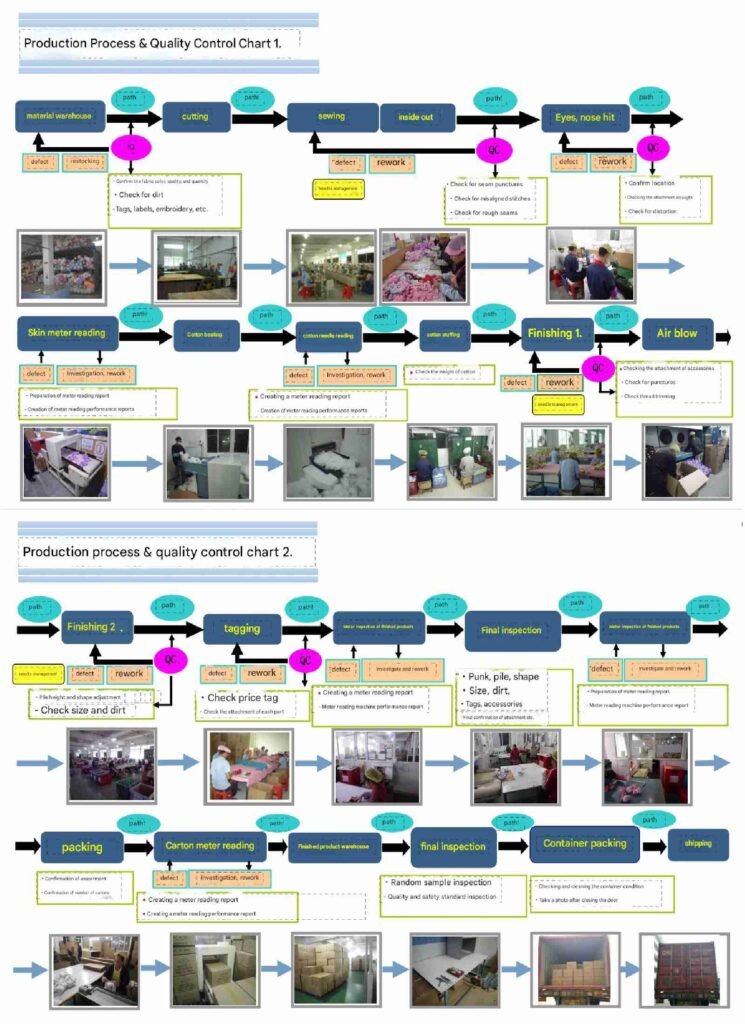

The real process is closer to product engineering than “cute toy making.” A good factory doesn’t just stitch a prototype. It builds a repeatable system: clear RFQ inputs, version-controlled sampling, structured approvals, QC checkpoints, and shipment-ready packing.

A custom plush toy manufacturing process runs from RFQ and design conversion to sampling, approvals, bulk production, QC, compliance planning, and shipment-ready packaging. The fastest path is a factory-ready RFQ with clear size, materials, face method, accessories, packaging level, target quantity, and destination market requirements. A Ready plush manufacturer uses documented workflows, version control, QC gates, and pre-production approvals to keep bulk consistent and timelines stable.

Now let’s break down what really happens—step by step—and how you can choose a supplier who performs like a true manufacturing partner, not a “sample-only” workshop.

What is the custom plush toy manufacturing process?

The custom plush toy manufacturing process is a structured workflow used by brand owners, IP creators, retailers, and distributors to turn artwork into bulk-consistent plush products. It includes RFQ inputs, pattern engineering, sampling revisions, golden sample approval, material sourcing, production planning, QC checkpoints, compliance preparation, and packaging/shipping readiness. It’s built for repeatability—so the bulk matches the approved sample and reorders stay consistent.

A plush project usually starts with one of three realities:

- You have an IP or character (book, game, mascot, creator merch) and need the plush to match expression, proportions, and brand style.

- You have a retail or eCommerce channel (Amazon, Shopify, chain stores, gift shops) and need packaging, barcodes, and stable SKU repeatability.

- You have a promotional program (events, corporate gifts, sports teams) and need budget control, short lead times, and predictable delivery.

All three cases share one hidden challenge: plush is handmade at scale. That means bulk success depends less on “how cute the sample looks” and more on how well the factory controls the process that creates thousands of units.

Here’s the process in plain language:

- RFQ (Request for Quote): You define what you want in manufacturing terms, not just in marketing terms.

- Design-to-manufacturing conversion: Artwork becomes patterns, sewing routes, and face placement rules.

- Sampling: The factory builds prototypes, collects feedback, and makes revisions with version control.

- Approval: You sign off on a final “golden sample,” plus key specs and tolerances.

- Bulk prep: Materials are ordered, production lines are briefed, and pre-production checks happen.

- Production + QC: Work is monitored during sewing, stuffing, trimming, and packing.

- Compliance + packaging + shipment readiness: The goods are packed for your channel and destination.

The most common mistake is treating this like a one-time craft job. For B2B, plush is closer to a system where every decision has a downstream effect.

For example:

- If you choose long-pile fabric for a premium look, it can soften face details, which changes the best face method (embroidery vs printing) and increases revision cycles.

- If you add accessories (key rings, zippers, webbing straps, clips), you introduce safety, sourcing, and assembly complexity that affects quoting and timing.

- If you want retail-ready packaging, you need early decisions on box dimensions, barcode placement, and carton marks—or your finished goods sit waiting for packaging materials.

This is why we will asks structured questions, flags risks early, and documents decisions so the bulk result doesn’t drift.

At Heyzizi, we treat plush development like a managed workflow: RFQ → sampling → approval → mass production → shipment, with clear checkpoints for materials, workmanship, QC, and packaging readiness. We support custom plush products across styles and functional categories (classic plush, mascot plush, keychain plush, plush accessories, plush gift items), and we work with and premium brands that need stable quality and repeatable output.

How do you write a factory-ready RFQ (what, which, and why details matter)?

A factory-ready RFQ is the fastest way to get an accurate quote and avoid delays. It should specify plush type, size, target weight, fabric and filling preferences, face method, accessories, packaging level, target quantity by SKU, destination market, and timeline. Good RFQs include artwork files, reference photos, tolerance expectations, and channel needs (retail vs eCommerce). Missing specs often cause re-quoting and extra sampling rounds.

If you want fewer surprises, your RFQ should read like a manufacturing brief, not a mood board.

A quote can only be accurate when the factory knows what it is pricing. Plush pricing isn’t just “size × fabric.” It’s a mix of:

- Materials (outer fabric, lining if any, filling, trims)

- Workmanship time (pattern complexity, seam count, embroidery time, assembly steps)

- Accessories (zippers, rings, clips, woven labels, hangtags)

- Packaging level (polybag vs color box vs display carton)

- Compliance expectations (market requirements, labeling)

- Order structure (how many SKUs, how many per SKU, repeat orders)

Below is a practical RFQ checklist you can copy-paste into your inquiry.

RFQ Checklist Table

| RFQ Item | What to Provide | Why It Matters |

|---|---|---|

| Product type | Plush toy / keychain / mascot / plush accessory | Drives pattern + assembly steps |

| Size | Height/length + tolerance (e.g., ±1 cm) | Controls pattern and bulk consistency |

| Target weight | Total weight range (e.g., 180–200g) | Impacts stuffing density + cost |

| Artwork files | AI/PDF/PSD + front/side/back refs | Prevents interpretation drift |

| Face method | Embroidery / printing / hybrid | Big cost + quality driver |

| Fabric preference | Pile length, feel, color refs, GSM target | Changes look + durability |

| Filling | PP cotton / high-resilience / weighted beads | Affects feel + weight stability |

| Accessories | Zipper, ring, clip, strap, labels | Adds sourcing + safety steps |

| Packaging level | Polybag / hangtag / color box / gift box | Changes unit cost and lead time |

| Quantity + SKU split | Total qty + qty per SKU/color | Pricing tier + production planning |

| Destination market | US/EU/UK/other | Testing + labeling planning |

| Timeline | Sample deadline + ship date | Helps plan materials + line schedule |

A “good RFQ” does something: it tells the factory how you will judge success.

Examples

success rules:

- “Face must match this reference expression; eye distance can vary within 2–3 mm.”

- “Plush must stand on shelf; no forward leaning.”

- “Fabric must feel soft but not shed; avoid heavy lint.”

- “Packaging must fit Amazon FBA labeling workflow.”

When you don’t define these, the factory guesses. And guessing is expensive in sampling time.

What information does a plush factory need to quote accurately?

In short: product definition + channel definition + risk definition.

- Product definition: size, materials, face method, accessories, complexity

- Channel definition: retail/eCommerce, packaging requirements, labeling

- Risk definition: what can vary vs what cannot vary, and what must be tested

Why “missing specs” causes delays and cost surprises

When an RFQ lacks details, the factory either:

- quotes conservatively (higher price), or

- quotes loosely (then revises after sampling), or

- produces a sample that looks good but cannot be repeated in bulk.

If your goal is speed plus accuracy, a factory-ready RFQ is the cheapest “tool” you can use.

Which type of plush manufacturer is best: trading company vs direct factory vs one-stop OEM/ODM?

The best plush supplier model depends on control and accountability. A direct factory offers faster technical alignment and clearer QC ownership. A trading company can help with coordination but may add layers that slow version control. A one-stop OEM/ODM manufacturer is best for B2B programs when it provides documented sampling, stable sourcing, QC gates, compliance support, and shipment-ready packaging. We should ask who owns patterns, revisions, and corrective actions.

This is a question that deserves a realistic answer: there’s no “one model” that fits every project. What matters is who owns the details that make bulk consistent.

Trading company

A trading company can be helpful when you need multi-factory sourcing, language support, or consolidated shipping. The risk is that technical decisions get filtered.

Common pain points:

- You ask for a change; it gets paraphrased; the factory interprets it differently.

- You lose track of sample versions because the “middle layer” doesn’t run strict version labeling.

- QC ownership is unclear—who fixes what when defects appear?

Direct factory

A direct factory relationship can move faster because you talk to the people who control patterns, sewing routes, and QC methods.

What improves:

- Faster problem-solving during sampling

- Clearer ownership of pattern files and workmanship notes

- More consistent handover from sample room to production line

What you still must check:

- Is the factory structured for B2B workflows, or is it a “sample-focused” workshop?

One-stop OEM/ODM

For B2B, “one-stop” is valuable only when it’s real, not a brochure word.

A ready one-stop plush manufacturer should cover:

- design conversion + pattern engineering

- fabric and trim sourcing with backup options

- sampling with version control

- production readiness checks

- QC gates + defect prevention system

- packaging + labeling readiness

- shipment coordination support

What makes a plush manufacturer “ready”?

Here’s a practical checklist you can use in supplier evaluation calls.

Ready Manufacturer Checklist

| Area | What “ready” looks like | Benefit |

|---|---|---|

| Sampling system | Version labels, change list, measurement sheet | Faster approvals |

| Documentation | Tech pack handling, workmanship notes, tolerance rules | Bulk matches sample |

| Supply chain | Stable sourcing + alternative material plan | Fewer delays |

| QC structure | Inline checks + final inspection standards | Lower defect risk |

| Packaging readiness | Barcode/SKU logic, carton marks, packing list control | Channel compliance |

| Communication | Recap summaries, clear questions, photo proof | Less misinterpretation |

| Reorder control | Standardized specs + archived sample references | Repeatable reorders |

How do I know this is real?

You test it by asking for:

- a sample revision process example (how they track changes)

- a basic QC flow (what they check and when)

- a packaging/labeling example (barcode placement, carton mark format)

- a timeline breakdown (materials lead time vs sampling vs production)

If the supplier answers with structure, they are likely built for B2B. If the supplier answers with vague promises, you’re likely buying risk.

At Heyzizi, we operate as a factory-side partner with a documented workflow, fast sampling support, low MOQ options, and a focus on consistent bulk output. For serious programs, we treat “repeatability” as a core deliverable, not an afterthought.

How does design-to-manufacturing conversion work (artwork → patterns → sewing paths)?

Design-to-manufacturing conversion turns artwork into patterns, seam routes, and face placement rules that can be repeated in bulk. Patterns control proportions, seam allowances, and stuffing access points, while sewing paths control how fabric tension and shape stability behave. Will get better bulk consistency when they approve not only the look, but also key measurements, face placement tolerances, and a final golden sample. This stage is also where design protection steps should start.

A plush toy is a 3D object built from 2D pattern pieces. That conversion is where many “cute sample, inconsistent bulk” stories begin.

How patterns and sewing routes protect shape consistency in bulk

Two plush toys can use the same fabric and the same artwork, but look different in bulk because:

- the seam allowance isn’t controlled

- the stitching route changes fabric tension

- stuffing access points shift or get resized

- curved seams are handled differently by different operators

A strong factory converts your concept into:

- pattern pieces that define proportions

- seam allowances that control final size

- alignment marks that lock face symmetry

- sewing routes that reduce distortion

- stuffing rules that define firmness and weight consistency

If your plush must “sit” or “stand,” structure planning matters even more. Stability isn’t magic; it’s weight balance, base shape, and controlled stuffing density. That’s why a factory will ask questions like:

- Should it stand on a shelf without support?

- Is it okay if it leans slightly, or must it be upright?

- Is the head intentionally oversized, and if yes, how do we counterbalance?

These are engineering questions in plush clothing.

How to protect your design when working with a plush supplier

Design protection is another topic usually think about too late. A practical approach doesn’t rely only on legal documents; it uses process control.

Here are pragmatic steps that protect you without slowing development:

- Share files in layers. Start with watermarked previews and limited-resolution references. Provide print-ready artwork only after you align on quote scope and partnership seriousness.

- Lock versions. Use version naming: “V1,” “V2,” “Final for Sample,” “Golden Sample.” Require the supplier to repeat the version label in every photo and message.

- Separate IP assets. Art IP is one thing. Pattern files and workmanship notes are another. Clarify ownership boundaries early.

- Use an NDA, but don’t stop there. An NDA helps, but process discipline prevents leakage more effectively than paperwork alone.

- Create a “must-match list.” Spell out what cannot change: face ratio, key colors, signature details, logo placement. When a supplier understands your non-negotiables, “accidental redesign” risk drops.

Design Protection Workflow Table

| Stage | What to Share | Protection Move |

|---|---|---|

| Early quote | Watermarked refs + simple specs | Limit editable files |

| Sampling start | Layered artwork + key dimensions | Version control rules |

| Pre-production | Final artwork + golden sample details | Written approval + archive |

| Bulk | Workmanship notes + QC standards | Controlled access + traceability |

If a supplier resists version control or refuses to document changes, treat that as a business signal. In B2B plush, communication discipline often predicts manufacturing discipline.

What materials and trims should you choose (and which options control feel, durability, and price)?

Material choices control the plush’s feel, durability, and pricing more than expect. Key variables include pile length, fabric GSM, backing strength, color fastness, and shedding behavior. Filling choices affect firmness and weight consistency, while trims and accessories add sourcing and failure risk. We should define material specs in the RFQ, select face methods that match fabric texture, and plan packaging to protect shape during storage and shipping.

Plush is tactile. touch it, squeeze it, and judge quality in seconds. That’s why material decisions are not “detail work.” They are the product.

Which material specs matter most for B2B quality (and how to write them)

When we say “soft plush,” factories hear many interpretations. Instead, write specs that can be matched.

Key fabric specs to define:

- pile length (short-pile vs long-pile)

- GSM (fabric weight)

- backing strength (impacts seam stability)

- color accuracy (Pantone or matched reference)

- color fastness expectations (rubbing, washing, light exposure)

- shedding tolerance (what level is acceptable)

Why this matters: long-pile fabric can hide seams and feel premium, but it can also blur face details. Short-pile supports sharper faces and cleaner embroidery edges, but may feel less “fluffy.”

Filling options and what they change

Filling is not only comfort; it controls shape memory.

Common filling choices:

- PP cotton (standard): soft, cost-friendly, widely used

- high-resilience filling: better bounce back, stronger shape retention

- weighted beads: adds premium “heft,” but needs careful safety and inner bag control

Experience depends on weight (for example, a desk buddy plush or a calming weighted plush), you should specify:

- target weight range

- bead location (base vs body)

- inner bag structure to avoid bead migration

Which trims and accessories increase failure risk

Accessories can add value, but they add risk if not engineered well.

Examples:

- key rings / lobster clasps: stress concentration at attachment points

- zippers: need seam reinforcement and smooth operation checks

- webbing straps: require bartack reinforcement, plus edge finish control

- labels / hangtags: add packaging steps and compliance labeling logic

- magnets: require careful safety planning for certain markets

A ready supplier will call out risk early rather than saying “yes” to everything. That’s a good sign, even if it feels less friendly at first. You’re not buying friendliness; you’re buying predictability.

Packaging decisions that protect the product you paid for

Plush is vulnerable to deformation during storage and shipping. If you ship long distances, packaging needs to protect:

- face flattening

- seam compression marks

- accessory scratching

- dust and moisture exposure

This is why packaging is not a “last step.” It is part of product quality.

If you plan retail boxes or blind box displays, define packaging early so the plush dimensions and posture match the box reality.

Embroidery vs printing: which is better for plush faces and logos (and when to use both)?

Embroidery is often best for durability, premium texture, and long-term retail handling, while printing is best for fine gradients, illustration detail, and complex color areas. The best choice depends on fabric pile, face size, and the expression accuracy you need. Many B2B programs use a hybrid method—embroidered outlines with printed fills—to balance clarity, cost, and repeatability in bulk production.

This decision can make or break your product perception. A plush face is the first thing people judge, and face mistakes create instant returns.

Embroidery vs Printing Comparison Table

| Factor | Embroidery | Printing |

|---|---|---|

| Durability | Strong for abrasion | Depends on ink/process |

| Detail | Good for clean shapes | Great for gradients and fine art |

| Feel | Raised texture | Smooth surface |

| Cost driver | Stitch count/time | Print area + setup |

| Best on fabric | Short/medium pile | Short pile or smooth panels |

| Risk | Stiffness if dense | Smudging if poor process |

When embroidery wins

Embroidery works well for:

- simple, bold eyes and mouth shapes

- premium “handcrafted” look

- logos that need texture and long-term handling durability

But embroidery has a trade-off: high stitch density can stiffen a face panel and change the plush’s feel. A good factory controls this with:

- stitch density optimization

- underlay choices

- stabilizer selection

- panel reinforcement rules

When printing wins

Printing shines when you need:

- gradients

- painterly art

- complex patterns inside eyes

- soft facial shading

Printing can also keep the face panel softer than heavy embroidery.

But printing also needs process discipline. We should ask:

- what print method is used (screen, heat transfer, sublimation, etc.)

- how color accuracy is controlled

- how abrasion resistance is checked

Hybrid solutions that reduce risk

Many high-performing plush programs use hybrid solutions:

- embroidered outlines (locks expression shape)

- printed fills (adds detail without heavy stitching)

Hybrid is especially useful when:

- your character has detailed eyes but must stay cute and consistent

- you want premium face clarity without turning the face into a stiff patch

The real “best method” is the one your supplier can repeat reliably in bulk with your chosen fabric. That’s why this decision belongs inside the sampling workflow, not as a quick choice on day one.

How long does sampling take, and how many revisions are normal?

Sampling timelines vary by complexity, material lead time, and revision cycles. Simple plush projects may take a few weeks for first prototypes, while complex designs with accessories or special fabrics take longer. Most projects require multiple revision rounds for face expression, proportions, stuffing density, and seam tension. Reliable suppliers shorten cycles by using version labels, change lists, measurement sheets, and clear communication that confirms what changed and why.

Typical Timeline Table

| Stage | Typical Range | What Changes It |

|---|---|---|

| RFQ clarification | 1–3 days | Missing details, unclear packaging |

| First sample | 3–7 days | Complexity, fabric sourcing |

| Revisions | 7–14 days each | Face accuracy, structure changes |

| Golden sample approval | 2–7 days | Internal approvals |

| Bulk production | 10–30+ days | Qty, line schedule, packaging |

What revisions are normal?

Most plush revisions focus on:

- face position and expression accuracy

- proportions (head/body ratio, limb length)

- stuffing density (too soft vs too hard)

- seam tension and shape stability

- accessory placement and strength

A “good revision cycle” is not random. It is documented:

- what changed

- why it changed

- what measurement changed

- which version is current

What communication style predicts a reliable plush supplier?

This is one of the strongest predictors of supplier quality.

Reliable communication patterns:

- They ask structured questions early (not after the sample is done).

- They recap decisions in simple bullet points.

- They label sample versions clearly in photos.

- They provide measurement sheets when size matters.

- They flag risks (fabric shedding, face distortion, accessory stress).

Red flags:

- “No problem” replies without details

- no version labeling

- changing timelines without reasons

- no photo proof

- no change list between versions

Here’s a friendly template you can request:

- “Please send sample photos with a version label in every image.”

- “Please list all changes vs last version in bullets.”

- “Please include key measurements: height, width, face distance, and weight range.”

A supplier that can do this smoothly is usually a supplier that can run bulk smoothly. Communication discipline often mirrors production discipline.

What is MOQ, and why do small orders cost more than bulk?

MOQ is the minimum order quantity that makes production viable based on material purchasing, line setup, and labor efficiency. Small orders often cost more per unit because materials are bought at higher prices, setup time is spread across fewer units, and production learning curves are shorter. Bulk orders lower costs through tiered material pricing, higher line efficiency, and more stable workmanship consistency. Compare quotes using the same scope and packaging level.

MOQ is often misunderstood. We hear MOQ and think suppliers are being difficult. The reality: MOQ is tied to the economics of making a physical product.

A plush order has “fixed work” that must happen no matter what:

- pattern work and sampling setup

- production line briefing and training

- material purchasing and cutting preparation

- QC planning and packing workflow

When you spread that across 300 units, the cost per unit is naturally higher than spreading it across 3,000 units.

Small Order vs Bulk Order

| Cost Driver | Small Order | Bulk Order |

|---|---|---|

| Material price | Higher per meter | Lower via tier pricing |

| Setup cost | High per unit | Diluted across volume |

| Efficiency | More interruptions | Smoother line rhythm |

| Consistency | More variation risk | More stable output |

| Packaging | Often customized later | Planned earlier, smoother |

This doesn’t mean small orders are bad. Small orders are often smart for testing demand. It just means the expect:

- higher unit cost

- tighter scope control

- less room for “extra changes”

What a complete quote should include

A B2B quote should not be one line. It should clarify:

- unit price scope (what is included)

- packaging scope (polybag vs box, barcode, hangtag)

- sample fees (refundable or not, conditions)

- tooling or special process fees (if any)

- testing expectations (if required)

- payment terms and production timeline assumptions

If you compare quotes without aligning scope, you’ll choose the lowest number and pay the difference later.

At Heyzizi, we support low MOQ options for many plush categories, while keeping the development workflow intact. Even for small orders, the key steps (sampling, approvals, QC rules) still matter—because skipping steps creates defects and rework.

What QC and safety testing should require and why?

We should require QC checkpoints from incoming materials to in-process inspection, finished goods checks, and packing verification. For markets like the US and EU, safety testing and compliance planning may be required depending on age grading and product features. Defect prevention focuses on seam strength, accessory security, embroidery stability, cleanliness, and deformation control. Testing should be planned early—after production is the worst time to discover compliance gaps.

Quality in plush is not “inspect at the end.” End inspection catches issues, but it doesn’t prevent them.

A strong QC system works like this:

- Incoming material checks Confirm fabric color, pile, defects, and trim quality before cutting.

- In-process checks (inline QC) Catch seam issues, face misalignment, stuffing problems while the work is still being done.

- Finished goods inspection Check appearance, measurements, accessory security, and surface cleanliness.

- Packing checks Confirm packaging match, barcode labels, carton marks, and packing list accuracy.

QC Checkpoints Table

| Stage | What’s Checked | Typical Issues Prevented |

|---|---|---|

| Incoming | Fabric flaws, color mismatch, trim defects | Shade drift, weak components |

| Inline | Seam strength, face alignment, stitching quality | Bulk inconsistency |

| Final | Appearance, measurement, weight range, cleanliness | Returns, complaints |

| Packing | Barcode/SKU, carton marks, deformation protection | Warehouse problems |

Safety and compliance planning

If your product is sold into regulated markets or targeted for kids, compliance can become non-negotiable. The biggest business mistake is leaving compliance as “a final step.”

Why? Because:

- materials and accessories may need specific specs

- labeling rules may require early packaging decisions

- test failures can force design changes (which can force resampling)

Ready supplier helps you plan:

- age grade considerations

- accessory safety risks

- documentation and traceability needs

- timing for third-party testing if your program requires it

Even when testing is handled by the customer’s side, the factory must build products that can pass. That is a shared responsibility, and it works best when planned early.

What packaging and shipment readiness should a factory support ?

Packaging and shipment readiness should match your sales channel. eCommerce often needs polybags, warning labels, and scannable barcodes, while retail may require color boxes, hangtags, display cartons, and clean shelf presentation. A factory should support SKU/barcode placement, carton marks, packing lists, and pre-shipment checks like carton photos and loading verification. Packaging should be planned early to protect plush shape and reduce deformation during transit.

Packaging is where many plush projects lose money quietly. A plush can be perfect, then arrive flattened, dusty, mislabeled, or packed in the wrong SKU mix.

The right packaging level depends on your channel:

- eCommerce / fulfillment: polybag, barcode label, warning label, master carton labels

- retail: color box, hangtag, brand inserts, display-ready carton

- blind box / collectible: strict box dimensions, consistency, and presentation standards

Barcode and SKU logic

Warehouses and retailers don’t care how cute your plush is if they can’t scan it.

A shipment-ready factory supports:

- barcode placement rules

- SKU labeling consistency

- carton marking format (SKU, quantity, destination)

- packing list accuracy

If you ship to 3PLs, these details prevent chargebacks and delays.

Deformation prevention

Plush deforms under pressure. Packaging must protect:

- face panel shape

- head shape

- embroidered surface from friction

- accessories from scratching or bending

If you have display boxes, also consider:

- box compression strength

- inner tray support

- how the plush sits inside the packaging

Pre-shipment proof we should request

Before goods leave the factory, request:

- packed carton photos

- carton marks confirmation

- random sample photos from finished goods

- packing list and SKU breakdown confirmation

These checks reduce “arrival surprises,” which are the most expensive kind.

Ready to Quote Your Custom Plush Project?

If you want a smoother path from idea to bulk production—without quoting surprises or endless revisions—send us your RFQ details (artwork, size, quantity, packaging level, destination market, and timeline). Our team will reply with practical recommendations on materials, face method, structure, sampling steps, and a realistic production plan.

Email us to start your custom project: info@heyzizi.com

FAQs

For custom plush, unit price and lead time are driven less by “how nice the artwork looks” and more by how executable your specs are. The biggest cost drivers are size (material usage, sewing time, stuffing time), face technique (high-density embroidery typically takes more labor than simple printing), accessory count (keychains, zippers, straps, clothing, Velcro patches add both materials and operations), and packaging/labeling requirements (hangtags, barcode placement, individual polybags, carton marks, carton labels, mixed-carton rules). Lead time is heavily influenced by approval speed and version discipline. If provides a structured RFQ early—size, quantity, SKU breakdown, target hand-feel, and channel requirements—sampling usually needs fewer rounds and bulk can start sooner. Delays often happen when packaging is discussed at the end or when multiple changes (expression, fabric, accessories, labeling) move at the same time, creating repeated rework loops. A reliable quote and timeline come from locking inputs early and confirminfg with photo proof + measurement proof rather than subjective descriptions.

| Category | What you should specify | Typical impact |

|---|---|---|

| Size & shape | Height/width, complexity | Bigger & more complex = higher cost, longer time |

| Face technique | Embroidery/printing/appliqué/safety eyes | More steps = higher cost, longer sampling |

| Accessories | Keychain, zipper, straps, clothing | Adds materials + operations |

| SKU plan | Single SKU vs multi-SKU | More SKUs = more sorting + packing checks |

| Packaging & labeling | Retail/FBA/warehouse rules | Late decisions = schedule risk |

What information affects unit price and lead time the most for custom plush manufacturing?

Yes, small trial orders are possible, but higher unit price at low quantity is normal in plush manufacturing. A plush project still runs through the full workflow even if you produce a small batch: artwork review, pattern development, material confirmation, production planning, QC checkpoints, packaging/labeling rules, and carton planning. These are fixed efforts that do not disappear when quantity is low, so the cost is distributed across fewer units. Material economics also matter. Fabrics, stuffing, and trims (hardware, zippers, webbing, labels) typically cost less at higher purchase volumes. Can also stabilize supply lots, reducing color drift and hand-feel variation. On the production floor, quantity improves efficiency—operators become familiar with one style, output increases, and defect rates usually drop, which lowers labor cost per unit. Low quantity can also become expensive when SKU count is high. A small total order split into many variants increases sorting, packing, labeling checks, and mix-up risks, adding time and inspection effort. For better value in a trial run, keep the first batch simpler: fewer SKUs, cleaner accessory structure, and locked packaging rules early.

Quick table: Trial order vs bulk order

| Item | Small trial order | Bulk order |

|---|---|---|

| Setup & development cost per unit | High (spread over few units) | Low (spread over many units) |

| Material purchase price | Usually higher | Usually lower |

| Line efficiency | Lower (learning curve) | Higher (repeatable workflow) |

| SKU complexity risk | Higher if many variants | Easier to standardize |

| Best use case | Market test / validation | Stable supply / scaling |

Sampling-to-bulk timing depends on design complexity, approval speed, and whether standards are locked before mass production. Simple shapes with clear references and fewer accessories can move quickly because there are fewer variables to control. Character plush with multiple accessories, detailed expressions, and multi-SKU breakdowns typically needs tighter version control. Delays usually come from unstable approval targets rather than factory speed. If request changes in multiple directions at once—expression adjustments, material switches, accessory updates, plus late packaging requests—each new revision resets the evaluation standard. Another common delay is the absence of a golden sample package. A buyer may say “follow the sample,” but without written must-match points, placement references, embroidery density cues, reinforcement rules, and packaging standards, bulk preparation becomes slow and repetitive. The fastest way to reduce rounds is to approve with proofs (fixed-angle photo proof + measurement proof) and to lock channel packaging rules early (barcode placement, carton labels, carton marks, mixed-carton rules). This prevents late-stage surprises and makes the bulk schedule more predictable.

Quick table: Common delay triggers & prevention

| Delay trigger | What it looks like | Prevention |

|---|---|---|

| Moving targets | Many changes in parallel | Prioritize consistency items first |

| No placement standard | “Looks slightly different” | Lock centerline/eye line/boundaries |

| Late packaging rules | Labeling added near shipment | Confirm channel requirements early |

| Vague acceptance | “Not sure if OK” | Use tolerances + proof-based approval |

Face technique selection impacts detail level, durability, cost, and bulk consistency. Common options include embroidery, printing, applique, safety eyes, and mixed approaches (embroidery + printing, applique + embroidery). A practical way to choose is to start from channel and audience. For children-focused products, retail gift programs, or items needing strong abrasion resistance, embroidery is often preferred because the look holds up over handling and washing friction. Printing can capture gradients and very complex visuals, but plan for durability requirements and color-lot control across production. Applique adds a layered, premium feel—great for bold shapes or brand marks—but edge finishing and stitching quality become critical for long-term durability. Safety eyes can create strong expression effects, but they add assembly steps and QC pull checks, and consider target-market safety expectations and attachment reinforcement. Size also matters: micro details may not stitch cleanly on small plush keychains, while larger plush often benefits from applique layering. A stable method is to evaluate feasibility early and offer two build paths—standard vs premium—then lock must-match points into the golden sample package.

Quick table: Technique selection guide

| Technique | Strength | Watch-outs | Best for |

|---|---|---|---|

| Embroidery | Durable, clean, premium | Dense embroidery adds time/cost | Retail, kids programs, high handling |

| Printing | Gradients, complex art | Durability & color control | Detailed visuals, special graphics |

| Appliqué | Layered depth, premium | Edge finishing must be strong | Bold shapes, logos, large plush |

| Safety eyes | Strong “eye” effect | Pull checks, market rules | Character plush where allowed |

Keeping bulk consistent requires a documented system—unlocked materials and undefined placement standards are the main causes of drift. We recommend locking consistency in three layers. First is material lock: fabric pile direction and hand-feel reference, color control method (swatch reference or approved target), stuffing firmness direction, and trim specs (hardware, zipper, webbing, labels). Second is construction lock: panel logic, sewing method, reinforcement points at stress areas, and stuffing distribution rules to prevent dents or uneven feel. Third is placement lock: face centerline, eye line, spacing reference, embroidery boundaries, and accessory coordinates. These items should be written into a golden sample + pre-production package so production teams build to the same standard.

“Proof” is what makes remote control possible. Request fixed-angle photo proofs (front/side/back + close-ups), measurement proof at critical points (ruler + annotated points), and packing/labeling proofs (barcode placement, carton labels, carton marks, packing rules). For multi-SKU programs, include SKU confirmation and carton planning to prevent mix-ups and mislabeling that cause expensive rework.

Quick table: proof checklist

| Stage | Proof you can request | What it prevents |

|---|---|---|

| Sampling | Photo + measurement proof | Subjective approvals, revision loops |

| Pre-production | Golden sample package | Bulk drift across operators |

| Packing | Barcode + carton mark photos | Receiving delays, relabeling |

| Multi-SKU | Carton plan + SKU list | Mix-ups, wrong ratios |

Inspections often fail when teams rely on “overall feel” instead of defect categories linked to returns and channel issues. Plush defects typically cluster around face placement drift, embroidery loose threads or skipped stitches, seam weakness or uneven stitch lines, uneven stuffing that creates dents, loose accessories, and packaging/labeling errors that disrupt receiving. A practical QC structure uses four checkpoints: incoming inspection, in-line inspection, final inspection, and packing inspection. Incoming checks verify fabric lot stability (pile length, hand-feel direction, color reference) and trim spec consistency. In-line checks focus on face placement alignment and critical workmanship (embroidery boundary control, reinforcement at stress points, zipper-end stitching). Final inspection reviews symmetry and key measurements, plus spot checks for attachment strength. Packing inspection verifies barcode placement, hangtags, carton labels, carton marks, carton quantity, and mixed-carton rules.

Using a defect checklist accelerates decisions and reduces disputes. Categorize defects and define what is acceptable vs not acceptable early. This makes inspections repeatable and protects the buyer’s brand consistency.

Quick table: Plush defect categories

| Category | Typical defect | Business impact |

|---|---|---|

| Appearance/expression | Eye spacing drift, nose shift | Negative reviews, “not as pictured” |

| Embroidery | Loose threads, density drift | Rework, lower perceived quality |

| Seams/structure | Open seams, uneven stitching | Returns, durability issues |

| Stuffing | Lumps, dents, uneven firmness | Deformation complaints |

| Accessories | Loose keychain/zipper issues | Safety risk, replacements |

| Labeling/cartons | Wrong labels, mixed cartons | Warehouse delays, relabeling |

For FBA-ready and retail-ready plush programs, packaging and labeling issues can create more operational failure than the plush itself. Buyers often face barcode placement errors, carton label format mismatches, mixed-carton rules not matching the shipment, missing bag information, and unclear carton marks that slow receiving or trigger rejection. These problems create hidden costs: relabeling labor, repacking, delayed inbound schedules, and missed launch windows.

A stable approach is to lock packaging and labeling requirements early, based on channel needs. Decide the individual pack type (polybag, backer card, gift box), barcode placement (hangtag, bag outside, product tag position), carton label fields and placement, units per carton, single-SKU vs mixed cartons, carton numbering rules, and destination notes. During packing, buyers can request photo proof: barcode placement photos, carton label and carton mark photos, and inner packing layout. This reduces receiving friction and protects schedule reliability.

Quick table: Channel packaging focus

| Channel | Key packaging/labeling focus | Common failure |

|---|---|---|

| FBA/platform inbound | Consistent barcode placement, correct carton labels | Mixed carton mismatch, label misplacement |

| 3PL/warehouse | Clear carton marks, carton numbering, packing list | Missing fields, slow receiving |

| Retail stores | Hangtags/backer cards, scannable barcodes | Barcode hidden or damages presentation |

| Gift programs | Presentation + protection | Deformation in transit |

Multi-SKU programs succeed when complexity is managed as a system. With many colors, characters, and sizes, risk concentrates in (1) material lot control, (2) production rhythm control, and (3) packing/sorting control. The most common operational failure is mislabeling and mixing: carton labels show SKU A, but cartons contain SKU B, or variant ratios are wrong and the warehouse must re-sort. Another failure is drift across variants: face placement or embroidery density subtly changes between colorways, and the series loses uniformity.

A stable method is to run multi-SKU with three pre-plans. First, lock the SKU list and version standards: fabric color, face technique, accessory list, packaging method per SKU to avoid last-minute substitutions. Second, create a carton and labeling plan: units per carton, single-SKU vs mixed-carton rules, carton numbering, carton label fields and placement. Third, define consistency control points: golden sample alignment for key SKUs, placement reference standards in bulk, and category-based inspection across the series. For split deliveries, group cartons by destination early to reduce repacking and errors.

Quick table: Multi-SKU control plan

| Plan | What it includes | What it prevents |

|---|---|---|

| SKU lock | Spec per SKU, version control | Variant drift, wrong materials |

| Carton plan | Units/carton, mix rules, numbering | Mislabeling, wrong ratios |

| Consistency points | Placement refs, QC categories | Series inconsistency |

Plush look and hand-feel are heavily driven by fabric choice. Common directions include short-pile plush, ultra-soft minky-style textures, sherpa-like textures, long-pile plush, and printed plush fabrics. Trims often include keychain hardware, zippers, webbing, elastic, Velcro, woven labels, care labels, hangtags, backer cards, and plastic parts. Buyers care about repeatability: whether the next batch feels and looks like the first.

Variation usually comes from fabric lot changes, dye/print lot changes, and unclear color control rules. A stable approach is to lock an approved fabric swatch or the golden sample as the physical reference. Incoming inspection verifies pile length and hand-feel direction against that reference. For color, define swatch-based matching or Pantone-based targeting followed by physical approval. For printed plush, include print clarity and abrasion expectations in the standard to avoid washed-out patterns. Trim specs should also be locked, especially hardware and zippers, because thickness and smoothness vary across lots and affect perceived quality. Clarify substitution rules—what can be replaced and what cannot—to protect reorders.

Quick table: Variation sources & controls

| Variation source | Risk | Control method |

|---|---|---|

| Fabric lot change | Pile/hand-feel drift | Lock swatch + incoming check |

| Dye/print lot change | Color drift, blur | Define color method + physical approval |

| Trim lot change | Durability/feel changes | Lock trim model + substitution rules |

Compliance and safety requirements depend on target market, age grading, and channel rules. The earlier buyers clarify these conditions, the fewer late-stage changes occur. Children-focused products differ from adult collectibles. Items with safety eyes, magnets, beads, zipper pulls, or small metal accessories carry different risk points. Some channels also require specific label content, warnings, and material disclosures.

Buyers should prepare three types of information during development: target market and channel (labeling and warning expectations), age grade (whether small parts are allowed, how strong attachments must be), and structure/accessory list (what components carry risk). Process-wise, front-load controls for risk components: define reinforcement methods and pull-check expectations for attachment points, and confirm packaging information early. During sample approval, run functional checks like pull checks and seam checks at stress points. Building compliance into structure and workmanship is more reliable than trying to fix it after bulk starts.

Quick table: Development prep for compliance

| Topic | What to define early | Why it matters |

|---|---|---|

| Market/channel | Label/warning expectations | Avoid late packaging changes |

| Age grade | Small parts allowed? | Technique & attachment rules |

| Risk components | Eyes, magnets, metal parts | Reinforcement + inspection needs |

Reorder stability is a practical requirement. Producing a first order is one thing; reproducing the same character months later with different material lots requires preserved standards. Reorder drift happens when standards are lost: golden sample decisions not documented, BOM incomplete, placement references missing, tolerances unclear, packaging rules forgotten.

A reorder-ready project file solves this. It should include golden sample reference with must-match points, BOM (fabric, stuffing, trims, labels, hangtags), pattern and placement standards (centerline, eye line, embroidery boundaries, accessory coordinates), workmanship notes (embroidery density cues, reinforcement points, stitch expectations, stuffing distribution), QC checkpoints with defect categories, and packaging/labeling/carton rules (barcode placement, carton label fields, carton marks, mixed-carton rules, carton numbering). With this file, quoting is faster, approvals are clearer, rework is reduced, and the product line stays stable over time—especially for series characters and evergreen best-sellers.

Quick table: What goes into a reorder-ready file

| File section | Contents | Benefit |

|---|---|---|

| Golden sample | Must-match points | Prevents drift |

| BOM | Fabric/stuffing/trims | Stable sourcing |

| Placement refs | Lines/boundaries/coords | Expression consistency |

| QC standards | Defects + checkpoints | Lower complaint rate |

| Packing rules | Barcode/cartons/mix rules | Smooth receiving |

Many plush projects slow down because communication is inconsistent. Buyers can improve speed and predictability by keeping a single source of truth: one document or sheet where specs, versions, must-match points, and packaging rules are updated. This avoids confusion caused by scattered chat messages.

A recommended approval rhythm uses stage-based locks so teams do not reopen decisions repeatedly. In RFQ, lock size, quantity, SKU breakdown, channel requirements, and target hand-feel. In sampling, lock materials, structure, and placement references first; cosmetic refinements can follow once consistency is stable. In golden sample lock, finalize must-match points, workmanship notes, acceptance tolerances, and packaging/labeling/carton rules. During mass production, avoid unapproved substitutions; changes should follow a clear approval path.

Proof-based communication is also critical. When requesting changes, specify what to change, how much to change, and which photo/measurement baseline you are using. If the project is tied to a campaign date, plan milestones: sample approval, golden sample lock, bulk start, packing completion, shipment date. Milestones keep both sides aligned on what must be delivered and how it will be verified.

Quick table: Suggested approval rhythm

| Stage | Lock these items | Output proof |

|---|---|---|

| RFQ | Size/qty/SKU/channel | RFQ checklist |

| Sampling | Materials/structure/placement | Photo + measurement proof |

| Golden sample | Must-match + tolerances + packing | Pre-production package |

| Bulk | No substitutions without approval | QC checkpoints + packing proof |

For plush keychains, negative reviews rarely come from “it doesn’t look like the artwork.” They come from durability under real use: daily pulling, friction, drops, and hanging weight. The three critical areas are attachment structure, face wear resistance, and small-size pattern stability. The attachment point must be engineered as a load-bearing structure—not just stitched onto the surface. A more stable build uses reinforcement layers (backing + box stitches/backstitching) and defines pull-check points in QC. For the face, micro-size embroidery needs controlled density and boundaries: too dense can wrinkle, too light looks cheap and wears faster. Printing must consider abrasion resistance and color durability. Pattern-wise, small keychains drift easily—slight shifts create different expressions across bulk. Lock centerline, eye line, spacing reference, and technique boundaries before bulk.

In your RFQ, specify use case (bag charm, keys, promo giveaway), required pull strength expectations, hardware preference, and whether you need individual packaging to reduce abrasion. That allows the factory to propose an executable build and prevent durability issues during sampling, not after bulk arrives.

| Critical point | Common failure | Stable control |

|---|---|---|

| Hardware attachment | Loosening/detachment | Reinforcement + pull checks |

| Small face details | Wrinkle/fading | Density boundaries + wear checks |

| Bulk drift | Different expressions | Placement references locked |

Private label is not only adding a logo—it’s making brand presentation repeatable: consistent label placement, standardized hangtag fields, packaging alignment across SKUs, and scannable barcodes that match your channel rules. A practical plan covers four layers: on-product labels (woven label/care label/material info), hangtags and backer cards (retail display + information), individual packaging (polybag, gift box, display box), and outer carton information (carton labels, carton marks, carton numbering rules).

Most failures happen when label rules are not locked early: inconsistent hangtag holes and strings, barcodes placed where scanning is slow, or different SKU label positions causing warehouse inefficiency. A stable approach is to create a branding spec sheet that fixes size, placement, required fields, and print method—and approve it during sampling, not right before shipment.

If you serve multiple channels (DTC + retail + FBA), consider two packaging versions: a retail-display version and an inbound-logistics version. This prevents trading off shelf presentation against inbound compliance.

| Branding layer | What to lock | Common mistake |

|---|---|---|

| On-product labels | Placement/size/material | Inconsistent positions |

| Hangtags/backer cards | Fields + barcode position | Slow scanning |

| Individual pack | Protection needs | Deformation in transit |

| Carton info | Labels/marks/numbering | Missing fields |

Low MOQ is attractive, but need to know how it works in practice. MOQ is rarely a single fixed number; it is usually driven by material minimums, process complexity, SKU count, and whether trims are customized. Standard fabrics are easier for small runs, while custom-dyed colors, custom prints, custom hardware, or special zipper pulls often raise minimum thresholds. Technique complexity also matters: dense embroidery, multi-layer appliqué, or clothing structures increase preparation and QC effort. More SKUs increases sorting, labeling, carton planning work and mix-up risk—making low quantity more expensive per unit.

A stable approach is to treat low MOQ as a two-step program: a first run to validate look and channel packaging (fewer SKUs, simpler build), then a second run to scale volume and reduce unit cost. If you want the lowest barriers, choose readily available fabrics, avoid unnecessary custom trims in the first run, reduce SKUs, and lock packaging rules early.

| MOQ driver | Why MOQ rises | How to lower it |

|---|---|---|

| Custom dye/print | Material minimums | Start with stock colors |

| Custom trims | Tooling/minimums | Use standard trims first |

| Complex techniques | More prep/QC | Start with standard build |

| High SKU count | Sorting risk/cost | Reduce variants initially |

E-commerce brands care less about “can you make it” and more about stable delivery, consistent reorders, and low operational friction. Heyzizi operates in Guangdong with an 18,000㎡ facility, 600+ staff, in-house sales, development, design, a pattern room, and 80 QC specialists. For e-commerce brands, this matters because more steps can be handled internally, reducing handoff errors that happen with fragmented outsourcing. Strong QC also allows defect prevention during production, not just at the end.

E-commerce programs also depend heavily on packaging and barcode accuracy. Different platforms and 3PLs require specific labeling and carton rules. When factories lack a systematic labeling workflow, brands get stuck during peak season. A stable method is to confirm SKU lists, barcode placement, carton labels/marks, and packing rules during sampling, then lock them inside the pre-production package. This makes launches, replenishment, and reorders smoother and reduces inbound rework.

If you run multi-SKU fast launches, invest early in project files and reorder rules. It saves time and cost compared to re-explaining requirements every cycle.

| E-commerce priority | Supply-chain need | Stable control |

|---|---|---|

| Launch speed | Predictable lead time | Milestone planning |

| Reviews & returns | Bulk consistency | Golden sample package |

| Inbound efficiency | Accurate labeling/cartons | Early packaging lock |

| SKU expansion | Version control | Project file system |

Series character programs fail when each character looks good alone but the collection feels inconsistent together. Common causes include mixed fabric hand-feel across characters, different embroidery styles, inconsistent eye proportions/expression language, and inconsistent size tolerance control. The solution is to treat the series like a brand visual system: define family standards first, then extend characters under those rules.

Build a “series master standard” that unifies fabric direction (hand-feel baseline), face technique language (stitch style, density ranges, boundary style), proportion rules (eye ratio, spacing reference, head-body ratio ranges), and unified labeling/packaging style. Each character then adds controlled differences (colors, accessories, clothing) without breaking the family look. In bulk, apply the same acceptance method: the same defect categories, the same measurement points, and the same photo angles for approvals.

When the system is established, new character development becomes faster and cheaper because you are not reinventing standards for each SKU. For IP owners and e-commerce brands, this improves brand recognition and reduces long-term development cost.

| Family standard | What to unify | Benefit |

|---|---|---|

| Fabric baseline | Hand-feel/pile direction | Consistent touch |

| Face language | Stitch/density/boundary | Consistent expression |

| Proportion rules | Eye/head-body ratios | “Family face” look |

| Packaging/labels | Tags/barcodes/style | Brand consistency |

Clothed plush projects behave like “soft doll + garment system.” Failures often come from poor fit, unstable seam points, complicated wear/removal structures that reduce production efficiency, and fabric interaction (rubbing that causes pilling or color transfer). These risks increase at small sizes, where extra garment layers create distortion and inconsistency.

A stable approach starts by defining the garment role: fixed decoration (non-removable) or wearable/removable. Fixed garments are easier for bulk consistency and cost control. Removable garments create play value but require tighter size tolerances, better opening design, and stronger QC. Choose stable garment fabrics (low shrink, low color transfer) and do basic rub checks during sampling to reduce bulk surprises.

Clothing also affects the plush body’s stuffing feel and stress points. Lock garment pattern, fixation points, stitch expectations, and critical measurements in the golden sample package so bulk teams follow one standard.

| Failure point | Outcome | Prevention |

|---|---|---|

| Loose tolerances | Poor fit | Lock measurements + tolerances |

| Complex removable design | Low efficiency | Start with fixed version |

| Color transfer/pilling | Stains | Material choice + rub check |

| Weak fixation | Deformation | Reinforcement + in-line checks |

Retail plush feels “premium” through three signals: hand-feel, face execution, and finishing discipline. Premium does not always mean expensive—more often it means stable standards. For hand-feel, use consistent fabric lots and stuffing distribution to avoid dents and lumps. For the face, keep embroidery boundaries clean, maintain density consistency, and lock expression placement; for appliqué, edge finishing and stitch lines must be tidy. Finishing includes thread control, panel alignment, reinforced stress points, and label placement that doesn’t damage presentation.

To scale and reorder, these standards must be documented in the golden sample package, not left to “sample luck.” For retail series, set a family standard—fabric baseline, embroidery language, labeling style—and keep new SKUs within the same system. Packaging is also part of the premium experience: hangtags, scannable barcodes, and protective presentation packaging prevent deformation and improve shelf readiness. Lock packaging rules early, and replenishment becomes faster.

| Premium signal | What to standardize | Reorder benefit |

|---|---|---|

| Hand-feel | Fabric + stuffing uniformity | Less batch drift |

| Face quality | Clean boundaries + density | Stable expression |

| Finishing | Thread/panels/reinforcement | Lower returns |

| Packaging | Tags/barcodes/protection | Faster shelf readiness |

The biggest bulk disputes come from “you think it’s OK, I don’t.” The fix is to move acceptance from subjective to measurable: size tolerances, face placement deviation ranges, embroidery defect definitions, and packaging/labeling accuracy rules.

A practical approach uses two layers: non-negotiable failures and acceptable ranges. Non-negotiable examples: attachments must not loosen, barcodes must not be missing, severe face misalignment is not acceptable, obvious open seams are not acceptable. Acceptable ranges cover natural craft variation: size tolerances by area, small thread tails that can be trimmed, minor stuffing variation within a defined feel range.

Attach a defect-category sheet to the golden sample package and align once using a pre-production sample (PPS). Then inspections become table-driven rather than argument-driven. Here is a simplified template:

| Item | Non-negotiable failure | Acceptable range (example) |

|---|---|---|

| Measurements | Beyond tolerance | ±X mm by area |

| Face placement | Severe misalignment | Minor deviation within range |

| Embroidery | Broken/loose stitching | Small thread tails trimmable |

| Accessories | Loose/jammed | Minor resistance adjustable |

| Labeling/cartons | Wrong/mixed SKUs | Minor placement shift if scannable |

This clarity usually speeds delivery because both sides work toward the same target.

DTC brands reorder more frequently: rolling replenishment, small batches, seasonal variations. Speed comes less from pushing harder and more from assetizing the project. Build a project file per SKU: golden sample, BOM, placement references, workmanship notes, QC standards, packaging/labeling rules, carton templates. Then replenishment becomes a repeatable operation, not a restart.

DTC also depends on consistent customer experience—hand-feel, expression, size stability. Before reorders, run a quick alignment: confirm fabric lot; if lot changes, match to the golden sample for color/hand-feel; spot-check face placement reference points; reuse packaging and labeling templates.

For planning, segment SKUs into evergreen vs campaign styles. Lock materials and techniques tightly for evergreen SKUs to protect long-term stability. Allow more flexibility for campaign SKUs, but control versioning so campaign experimentation doesn’t disrupt evergreen supply.

| Reorder accelerator | Action | Benefit |

|---|---|---|

| Project file | Preserve specs + templates | Less back-and-forth |

| Lot alignment | Match to golden sample | Less drift |

| Template reuse | Same labeling/cartons | Smooth receiving |

| SKU layering | Evergreen vs campaign | Stable supply |

Fast progress requires two things: provide the minimum viable inputs to start, and the factory fills gaps with a structured checklist. The minimum inputs usually are artwork/references, target size, target quantity (trial + bulk), channel (retail/FBA/3PL), and must-match points (expression, hand-feel, accessories). share the target visual effect and budget range so feasibility recommendations can be made.

A stable rhythm follows four steps:

(1) quick feasibility review that highlights risks and offers two build paths (standard vs premium),

(2) lock the first sampling target—structure and placement before micro cosmetic changes,

(3) lock a golden sample + pre-production package that defines must-match points, acceptance standards, and packaging/labeling rules,

(4) run mass production milestones: PPS approval, production start, packing completion, shipment.

The most effective cooperation is structured feedback: each revision message should follow the same format (issue → desired change → reference photo/measurement). Keep versions clean. When both sides do this, sampling rounds decrease and bulk schedules become much more predictable.

| Stage | Buyer provides | Factory delivers |

|---|---|---|

| Feasibility | Artwork/size/channel | Risks + options |

| Sampling | Must-match points | Sample + proofs |

| Golden lock | Acceptance standards | Pre-production package |

| Bulk | Milestone approvals | QC + packing proofs |