Plush Toy Manufacturing Process & Quality Control

From concept to finished plush — developed and produced in our own factory

Plush toys are not “simple sewn products.” Every project involves fabric selection, pattern engineering, embroidery accuracy, hand-finishing, packaging decisions, and safety-focused quality checks.

Heyzizi is a B2B plush manufacturer under Jundong. We handle the full workflow in-house—from sampling to mass production—so brands, retailers, and IP creators get consistent quality, clear communication, and reliable delivery for long-term OEM/ODM cooperation.

Why Work Directly With Our Plush Factory

Choosing a plush manufacturer is not only about appearance. For B2B orders, what matters is process control, safety compliance, repeatable quality, and on-time delivery.

When you work directly with our factory team, you get transparent communication, faster decisions during sampling, and production managed to match your target market requirements.

Direct Factory Communication

Work with our development and production teams directly. You get clearer feedback, fewer misunderstandings, and faster sampling decisions.

Compliance Support for Key Markets

We support safety-focused production and testing preparation for EN71/CE (EU/UK) and ASTM F963 + CPSIA (US), based on your product age grade and sales channel requirements.

Sampling-to-Production Workflow

A structured process keeps every stage visible—from design review and quotation to prototype approval and bulk production—so your timeline stays under control.

Stable Production Capacity

In-house manufacturing helps us manage schedules, maintain consistency, and scale production smoothly when your program grows.

Controlled quality standards

We apply multi-stage QC across materials, sewing, stuffing, finishing, and packaging—reducing defects and improving repeatability for reorders.

Long-Term OEM / ODM Partnership

Built for brands and IP projects that need reliable, repeatable plush production with clear documentation, stable workmanship, and consistent delivery.

Why Plush Production Needs a Structured Process

For B2B plush programs, the biggest risks are inconsistency, unclear approvals, and avoidable rework during bulk production. A structured process solves that. With clear checkpoints—materials, pattern, sample approval, inline inspection, finishing, and final QC—you get better predictability on quality, timeline, and cost.

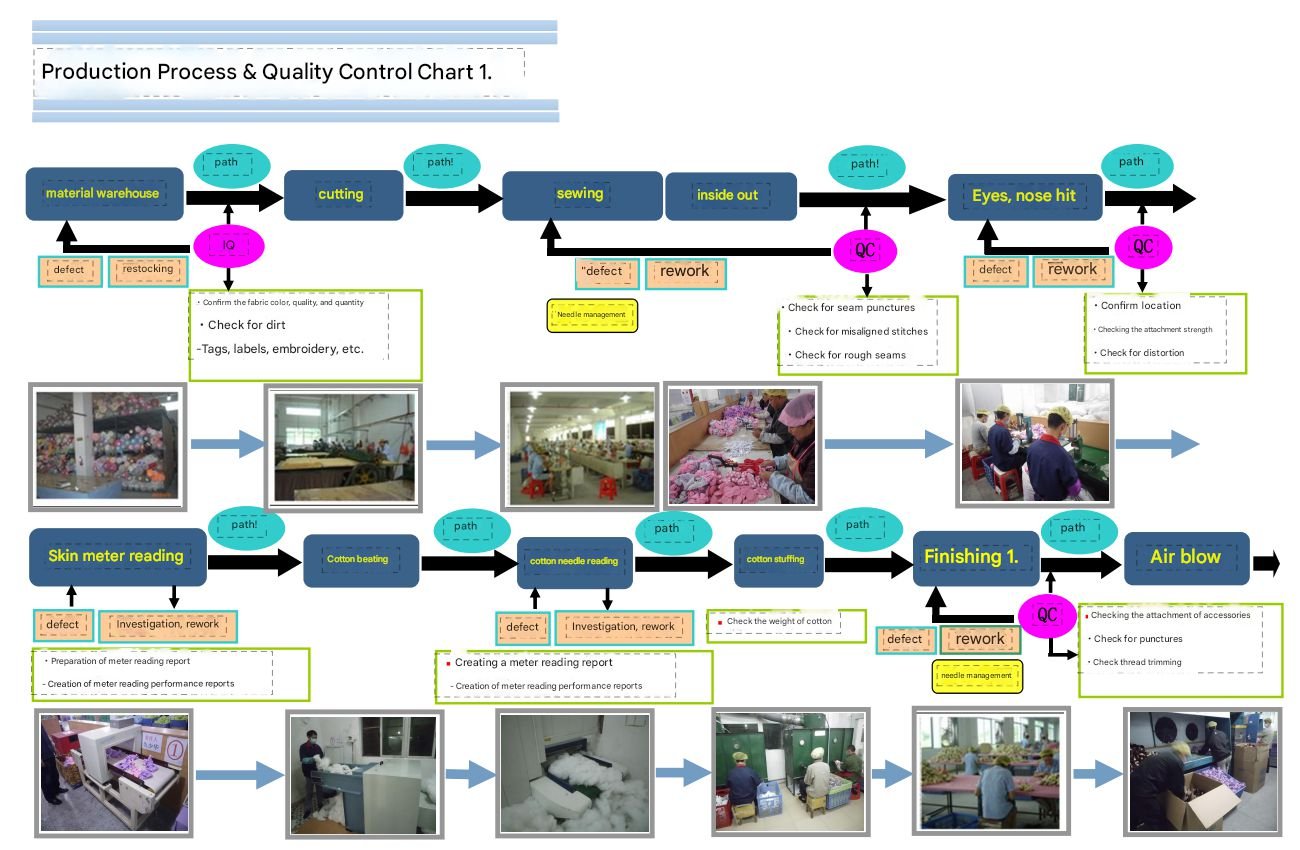

Our In-House Plush Manufacturing Process

Step 1 — Design Review & Quotation

Send your artwork, reference photos, or a sample. We review size, structure, fabric options, embroidery/printing, and target market requirements, then provide a clear quotation with sampling timeline.

Step 2 — Pattern Making & Material Selection

Our pattern team converts the design into production-ready templates. We confirm fabric, plush pile length, filling type, accessories, and stitching methods to match your quality and safety goals.

Step 3 — Prototype Sampling

We produce a prototype for shape, proportion, embroidery accuracy, and hand-feel. You’ll receive photos/videos (and sample shipment if needed) for feedback and revisions.

Step 4 — Sample Revision & Final Approval

We refine details such as stitching, facial expression, logo placement, and packaging requirements. Once the sample is approved, we lock the spec for bulk consistency.

Step 5 — Cutting, Sewing & Embroidery

Materials are cut and assembled with controlled sewing standards. Embroidery, printing, and accessory attachment follow approved specs with inline inspection to reduce defects early.

Step 6 — Stuffing, Shaping & Hand Finishing

Stuffing weight and firmness are controlled for consistent feel. We shape the plush, close seams cleanly, and complete hand finishing for a premium, retail-ready appearance.

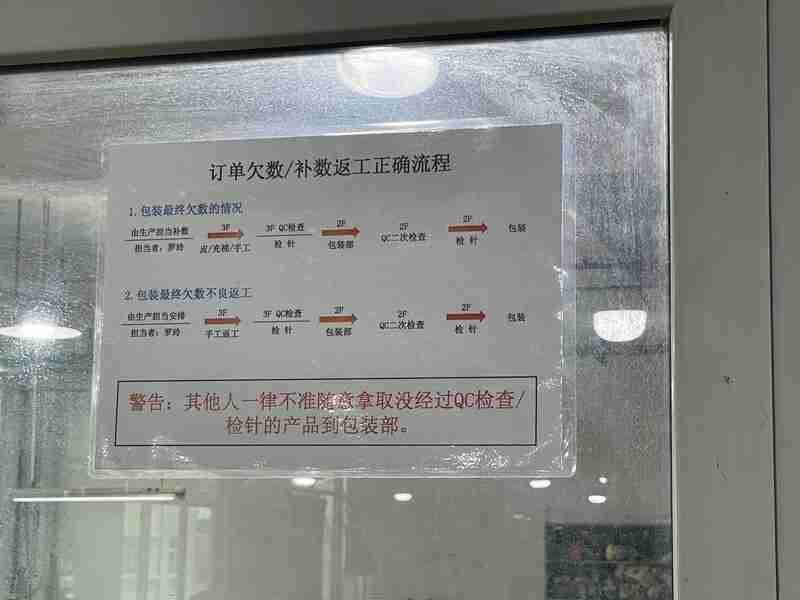

Step 7 — Needle Detection & Safety Check

Every finished plush passes through a needle detector to reduce metal contamination risk. We also perform appearance checks and workmanship verification based on your QC requirements.

Step 8 — Packing, Carton Drop Test Prep & Shipment

We pack by your preferred method—individual polybag, hangtag, inner box, or master carton. Labeling and carton specs are confirmed for safer shipping and smoother receiving.

Quality Control & Compliance Standards

Compliance and quality are essential in plush toy manufacturing, especially for products intended for children and global markets.

Our quality control system is designed to support recognized international safety standards, while maintaining consistent internal inspection procedures across all production stages.

We support EN71 / CE for UK & EU markets, ASTM F963 for the US market, and CPSIA compliance upon request. Internal QC standards are applied to every order to ensure safety, consistency, and long-term reliability.

Quality Control System for Plush Toy Manufacturing

Quality control is not a single inspection. It is a system applied throughout material selection, production, and finishing, Built into every stage, not added at the end.

In plush toy manufacturing, consistent quality cannot rely on final inspection alone. A reliable quality control system must be integrated into every production stage, from material evaluation and process control to finishing and final verification. This structured approach ensures stability, safety, and repeatable results in mass production.

QC Stage 1|Material Inspection

- Fabric texture & defects

- Color consistency

- Filling material quality

- Basic safety compliance

QC Stage 2|Sample & Pattern Verification

- Shape accuracy

- Proportion balance

- Stitching structure

- Filling distribution

QC Stage 3|In-Line Production Inspection

- Stitch strength

- Seam alignment

- Stress point reinforcement

QC Stage 4|Needle & Metal Safety Inspection

- Broken needle detection

- Metal prevention

- Safety risk elimination before next process

QC Stage 5|Stuffing & Shape Control

- Even filling

- Softness consistency

- Shape symmetry

QC Stage 6|Hand Stitching Inspection

- Secure closure

- Clean appearance

- Durability check

QC Stage 7|Final Appearance Inspection

- Size tolerance

- Stitching quality

- Label accuracy

QC Stage 8|Pre-Shipment Inspection

- Packaging accuracy

- Quantity check

- Carton condition

Detailed Plush Toy Production Process

Mass production is where plush toy quality is truly defined. Beyond design and sampling, consistency, durability, and safety depend on controlled manufacturing processes and skilled workmanship.

All mass production is carried out in our own factory by trained teams. From fabric cutting and sewing to stuffing, hand stitching, and final inspection, each step follows a structured workflow to ensure stable quality, precise execution, and reliable delivery for OEM and ODM projects.

01. Fabric Inspection & Pre-Shrinking

Before cutting, all fabrics are inspected according to internal standards, including color consistency, surface defects, texture stability, and cleanliness. For selected fabrics, pre-shrinking or relaxation treatment is applied to minimize deformation after sewing and stuffing. Only approved materials are released to production, ensuring consistent quality across mass production batches.

02. Laser Cutting / Precision Fabric Cutting

Based on finalized pattern files, fabrics are cut using laser cutting or precision cutting equipment. This process ensures clean edges, accurate shapes, and consistent sizing across all components. Precision cutting is particularly important for complex shapes, small details, and giant plush components, helping maintain structural accuracy and reduce material waste.

03. Embroidery, Printing & Detail Processing

Before sewing, facial features, logos, and decorative elements are applied using embroidery, screen printing, or heat transfer techniques. Performing these processes at an early stage improves accuracy and avoids rework after assembly. Accessories such as labels, patches, and fabric inserts are prepared in advance to ensure smooth assembly and batch consistency.

04. Skilled workers Sewing & Panel Assembly

Cut fabric panels are sewn together following defined seam paths. Stitch strength, alignment accuracy, and seam smoothness are controlled. Critical stress points are reinforced to improve durability, especially for large plush toys and frequently handled products.

05.Professional equipment Stuffing / Filling Process

High-quality filling materials are inserted using controlled stuffing machines combined with manual adjustment. Different plush areas may receive varied filling density to maintain balance, softness, and long-term shape stability. It will plays a key role in tactile quality and durability.

06. Hand Shaping & Quality Adjustment

After stuffing, each plush toy is manually shaped to adjust contours, symmetry, and proportions. Loose fibers are removed and surface smoothness is checked. This is a standardized process applied to every unit to ensure consistent appearance across production.

07. Hand Stitching & Closure Sewing

Stuffing openings are closed using hand stitching to ensure secure sealing, structural durability, and neat appearance. Stitch strength and invisibility are verified as part of manufacturing quality control, as this step directly affects safety and final product finish.

08. Needle Detection & Metal Safety Inspection

After sewing, semi-finished plush components pass through needle detection equipment to identify potential metal contamination. Any abnormal result is immediately isolated and corrected before proceeding to the next process.

09. Turning & Shape Preparation

After metal safety inspection, the plush shell is turned right-side out. Manual adjustment is performed to prepare the internal space for even stuffing and balanced volume distribution, ensuring stable shape and appearance in later stages.

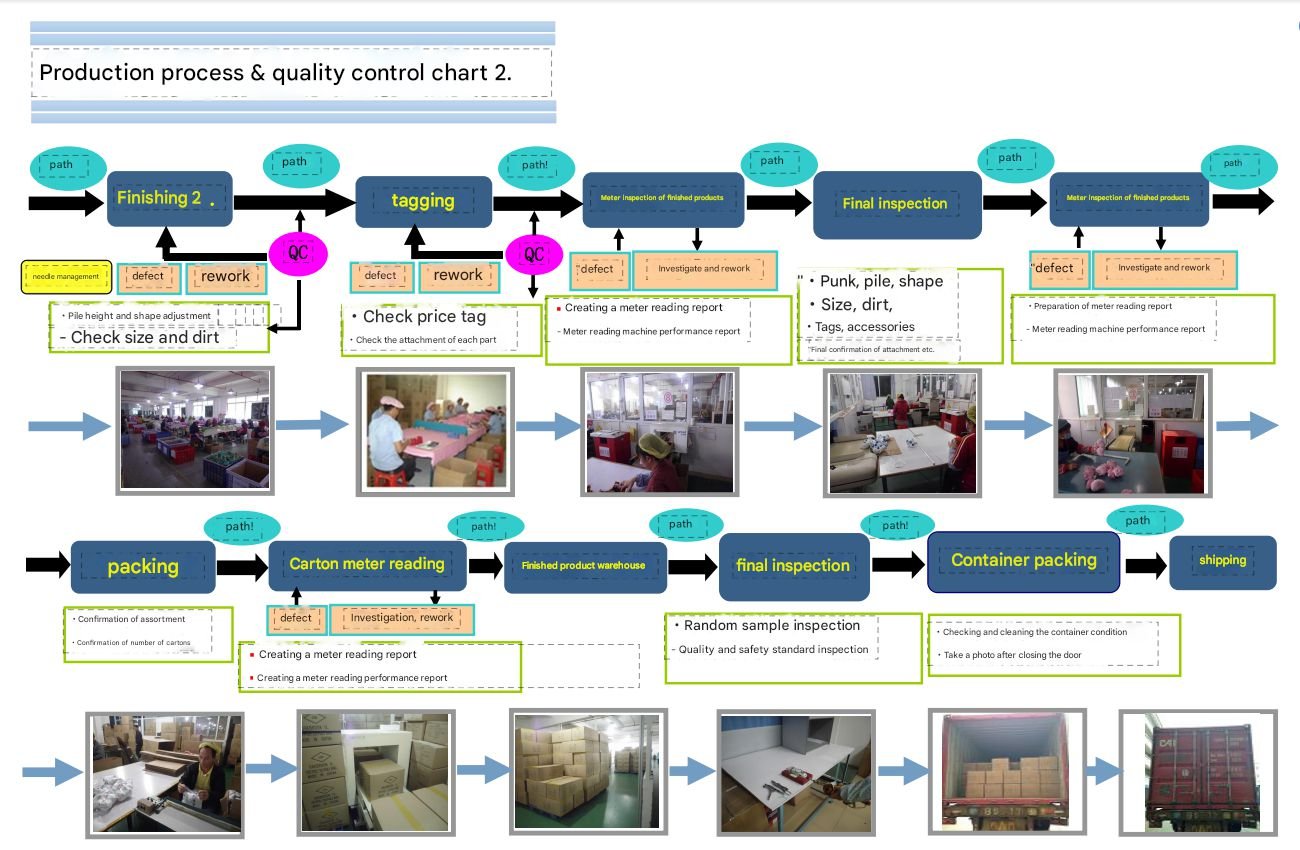

10. Professional team In-Line Quality Inspection

In-line quality inspections are performed throughout sewing, stuffing, and finishing stages. Any detected issues are corrected immediately, preventing defects from carrying over to later processes and ensuring stable production quality.

11. Final Trimming & Appearance Inspection

After assembly, excess threads and loose fibers are trimmed. Each plush toy is inspected based on appearance checklists, including shape, symmetry, stitching quality, size tolerance, and surface condition.

12. Labeling, Packaging & Carton Packing

Approved labels, hangtags, and packaging materials are applied according to confirmed specifications. Finished plush toys are packed into cartons following shipment standards and client requirements to ensure safe delivery.

Start your project with confidence!

Make a Sample of Your Plush Toys First?

Before mass production, a sample allows you to verify structure, materials, workmanship, and overall quality.

Our sampling process helps identify details early, reduce risks, and ensure your plush toys meet technical and quality expectations before moving forward.

Cooperating Brands Trusted

Trusted by brands for consistent plush manufacturing.

We work with brands across gift, retail, publishing, and promotional industries to develop plush toys with consistent quality and controlled production standards. From custom character plush to large-scale projects, our factory supports long-term cooperation built on trust, process transparency, and reliable delivery.

Selected Plush Toy Projects

Real-world examples from our OEM plush manufacturing work

Below is a small selection of plush toys we have developed and produced for our clients across different industries. Each project reflects our approach to material selection, pattern development, quality control, and production consistency. These examples demonstrate how we support brands with reliable plush manufacturing, from sample development to mass production.

Product & Production Video Overview

A closer look at our plush toys in-house manufacturing process

This video provides a real view of our plush toy production, from material preparation and assembly to finishing and quality inspection. By showing both the product details and the manufacturing environment, we aim to offer clear insight into how our factory operates and how quality is controlled throughout the process.

Frequently Asked Questions

Do you handle the entire plush toy production process in-house?

Sure. All core plush toy manufacturing processes are completed in our own factory rather than outsourced. This includes pattern development, fabric cutting, embroidery, sewing, stuffing, hand stitching, in-line inspection, final quality control, and packaging.

Managing the full process in-house allows us to maintain consistent quality standards, clear production scheduling, and direct communication. For OEM and custom plush projects, this structure reduces risk, avoids miscommunication between suppliers, and ensures that approved samples are accurately replicated during mass production.

Why is plush toy production more complex than it appears?

Plush toy manufacturing involves soft materials, three-dimensional structures, hand assembly, and strict safety considerations. Unlike flat textile products, plush toys require precise pattern engineering, controlled filling density, reinforced stress points, and repeated quality checks.

Small changes in fabric stretch, stitching tension, or stuffing volume can affect shape, durability, and safety. This is why a structured production process and experienced factory handling are critical for consistent results, especially for children’s plush toys and branded products.

How do you ensure consistency between samples and mass production?

Consistency is ensured by using the approved sample as the production benchmark. Patterns, sewing methods, filling specifications, and finishing standards are locked after sample approval and applied throughout mass production.

In addition, controlled cutting methods, defined sewing paths, and in-line inspections help maintain uniformity. This structured approach ensures that bulk orders match the confirmed sample in appearance, feel, and performance.

Is needle detection included in your plush toy production process?

Yes. Needle detection and metal safety inspection are integrated into our production process, particularly after sewing stages. This step helps identify broken needle fragments or metal residues that may occur during manufacturing.

Needle inspection is a critical safety control for plush toys, especially those intended for children. Any abnormal detection triggers immediate isolation and corrective action before the product proceeds to the next stage.

How do you control stuffing softness and shape stability?

Stuffing is controlled through a combination of machine filling and manual adjustment. Filling volume and density are carefully managed based on plush size, structure, and intended use.

Different areas of the plush may require varied filling density to maintain balance, softness, and long-term shape stability. This approach prevents overfilling, deformation, and uneven appearance during use or transport.

How many quality inspections are performed during production?

Quality control is not a single inspection but a system applied throughout production. Inspections include material inspection, in-line production checks, needle detection, final appearance inspection, and pre-shipment checks.

This multi-stage approach allows issues to be identified and corrected early, preventing defects from accumulating and ensuring stable quality throughout mass production.

Can you support safety and compliance requirements for different markets?

Yes. We support EN71 / CE compliance for UK and EU markets, ASTM F963 for the US market, and CPSIA compliance upon request. Testing can be arranged through qualified third-party laboratories when required.

Our internal production standards are aligned with these regulations to support smooth testing and certification.

What happens if quality issues are found during production?

If issues are identified during in-line inspections or quality checks, affected items are immediately isolated and corrected before moving forward. This prevents quality issues from reaching later production stages or final shipment.

This approach reduces rework costs and improves overall production stability.

How do you manage large or giant plush toy production?

Large and giant plush toys require additional structural planning. Stress points are reinforced, internal balance is adjusted, and filling density is carefully controlled to ensure stability and durability.

Our experience with oversized plush products allows us to manage shape retention and handling safety effectively.

Why is sampling recommended before mass production?

Sampling allows buyers to verify structure, materials, workmanship, and overall quality before committing to mass production. It helps identify potential issues early, reduce risks, and ensure expectations are aligned.

A confirmed sample serves as the technical and quality reference for mass production, improving efficiency and confidence.

Process & Manufacturing FAQs

These frequently asked questions address common concerns about our plush toy manufacturing process, quality control, and production management. They are intended to help buyers better understand how we develop, produce, and inspect plush toys in a factory environment before moving forward with sampling or mass production.